Throttle Application

1. Introduction

1.1 Overview

The Throttle application allows the user to implement a simple throttle control directly on the emDrive. Input devices can be connected directly to the emDrive and mapped to the throttle application. The application calculates the desired output based on these inputs and passes it to motor control. The output can be used as either a torque input or a speed input in the motor controller, depending on which CANOpen object the output is mapped to. No further configuration is needed to switch the application from one output mode to the other.

1.2 Features

The Throttle application supports the following features:

- Throttle Module

Functionality: Calculates the desired output based on mapped input and configuration parameters.

Capabilities: Can be configured as unidirectional or bidirectional. - Brake Module

Functionality: Calculates the desired brake torque based on mapped input and configuration parameters.

Capabilities: Unidirectional only, with brake torque always in the opposite direction to motor rotation.Note that if the desired output is speed, the brake should be disabled.

- Pump Control Module

Functionality: Controls the pump, turning it on or off depending on motor and drive temperature. - Pre-charge Module

Functionality: Manages the pre-charge process at startup. - DC-DC Turn On Delay Module

Functionality: Delays the activation of the DC-DC converter after startup to ensure controlled power application. - SOC Monitoring Module

Functionality: Monitors the State of Charge (SOC) of the battery.

Capabilities: Reduces the maximum allowed torque when SOC is below a specified threshold.Requires an external Battery Management System (BMS) to operate correctly.

- Charging Detection Module

Functionality: Detects when the battery is charging and disables the drive during the charging process. - Input Mapping

Functionality: Allows certain inputs to the throttle application to be mapped to CAN objects on the emDrive.

All throttle application features can be independently enabled or disabled (except the brake module, which requires the throttle module to be enabled). This is done by setting the Thr1_Enable CAN objects of the throttle application as detailed in Table 1.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

|

Thr1_Enable |

0x4010 | 0x00 |

Enables the throttle application: 1 – enabled (must be enabled for any modules to work) |

/ |

| Thr1_Enable__Throtle | 0x4011 |

0x03 |

Enables the throttle module: 0 – disabled |

Bit |

| Thr1_Enable__Brake | 0x4011 | 0x04 |

Enables the brake module: 0 – disabled |

Bit |

| Thr1_Enable__Pump | 0x4011 | 0x05 |

Enables the pump control module: 1 – enabled |

Bit |

| Thr1_Enable__Precharge | 0x4011 | 0x06 |

Enables the pre-charge module: 0 – disabled |

Bit |

| Thr1_Enable__DC_DC | 0x4011 | 0x07 |

Enables the DC-DC turn on delay module: 0 – disabled |

Bit |

| Thr1_Enable__SOC | 0x4011 | 0x08 |

Enables the SOC monitoring module: 0 – disabled |

Bit |

| Thr1_Enable__ChargingDetBitect | 0x4011 | 0x09 |

Enables the charging detection module: 0 – disabled |

Bit |

2. Input and Output mapping

Input and output mapping for the Throttle application is managed using the Thr1_Obj object, which stores the CANOpen indexes and subindexes of the inputs and outputs mapped to the Throttle application variables. You can remap any variable to a different input by writing the CANOpen index and subindex of the new input to the corresponding Thr1_Obj sub-object.

The following table outlines the object mapping parameters for the Throttle application. Each object in the table represents a specific function or control point within the application, and the corresponding CANOpen index and subindex define where these objects are located in the CANOpen network. By configuring these parameters, users can tailor the Throttle application to their specific needs, ensuring precise control and monitoring of various functions.

By correctly configuring these object mappings, users can ensure that the Throttle application communicates accurately with the various inputs and outputs connected to the emDrive. This flexibility allows for precise control of throttle, brake, pump, and other critical functions, enhancing the overall performance and reliability of the system.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Obj__AppControl | 0x4012 | 0x01 |

Address of CAN object where commands are sent to application |

Obj |

| Thr1_Obj__AppState | 0x4012 | 0x02 |

Address of CAN object where application state is saved |

Obj |

| Thr1_Obj__ThrotleVoltage | 0x4012 | 0x03 | Address of CAN object with throttle input | Obj |

| Thr1_Obj__ThrotleFWD_DIvalue | 0x4012 | 0x04 |

Address of CAN object to forward switch input |

Obj |

| Thr1_Obj__ThrotleREW_DIvalue | 0x4012 | 0x05 |

Address of CAN object to reverse switch input |

Obj |

| Thr1_Obj__TargetObj | 0x4012 | 0x06 |

Address of CAN object where output torque of throttle application is written |

Obj |

| Thr1_Obj__BatValid | 0x4012 | 0x07 |

Address of CAN object which stores BMS status. |

Obj |

| Thr1_Obj__BatSOC | 0x4012 | 0x08 |

Address of CAN object which stores battery SOC in percentage |

Obj |

| Thr1_Obj__BatState | 0x4012 | 0x09 |

Address of CAN object which stores battery state |

Obj |

| Thr1_Obj__ChargingDetectDIvalue | 0x4012 | 0x0A |

Address of CAN object which shows if charging is detected. If not 0 throttle application considers battery to be charging. |

Obj |

| Thr1_Obj__MainPumpEnableDO | 0x4012 |

0x0B |

Address of CAN object with main pump enable control |

Obj |

| Thr1_Obj__CoolingPumpEnableDO | 0x4012 | 0x0C |

Address of CAN object with cooling pump enable control |

Obj |

| Thr1_Obj__CoolingInputTemperature1 | 0x4012 | 0x0D |

Address of CAN object with temperature input 1 (default bridge heatsink temp) |

Obj |

| Thr1_Obj__CoolingInputTemperature2 | 0x4012 | 0x0E |

Address of CAN object with temperature input 2 (default motor temp) |

Obj |

| Thr1_Obj__DCDCenableDO | 0x4012 | 0x0F |

Address of CAN object with DC-DC enable control |

Obj |

| Thr1_Obj__BuzzerDO1 | 0x4012 | 0x10 |

Address of CAN object with buzzer high side enable control |

Obj |

| Thr1_Obj__BuzzerDO2 | 0x4012 | 0x11 |

Address of CAN object with buzzer low side enable control |

Obj |

| Thr1_Obj__BrakeVoltage | 0x4012 | 0x12 | Address of CAN object with break input | Obj |

| Thr1_Obj__RPM_in | 0x4012 | 0x13 | Address of CAN object with RPM data | Obj |

| Thr1_Obj__MainRelayEnableDO | 0x4012 | 0x14 |

Address of CAN object with main relay enable contro |

Obj |

| Thr1_Obj__PrechargeRelayEnableDO | 0x4012 | 0x15 |

Address of CAN object with pre-charge relay enable control |

Obj |

| Thr1_Obj__PrechargeDC_voltage | 0x4012 | 0x16 |

Address of CAN object with measured voltage during pre-charge procedure |

Obj |

2.1 Examples

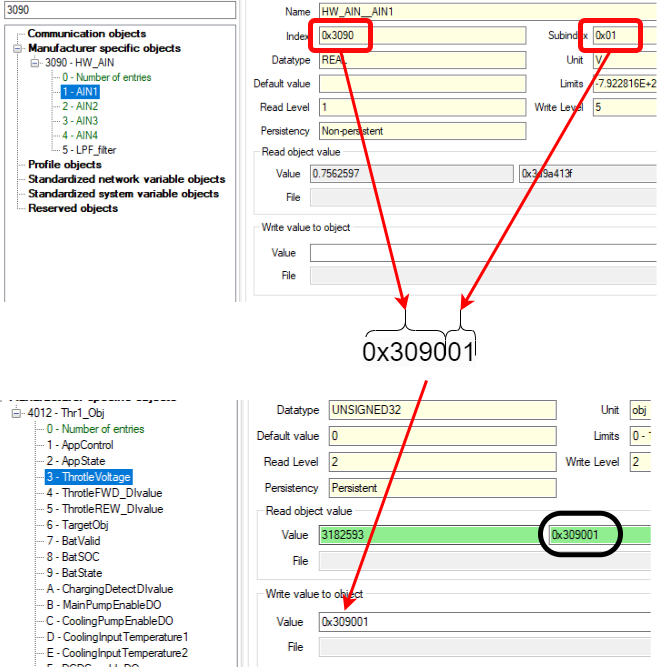

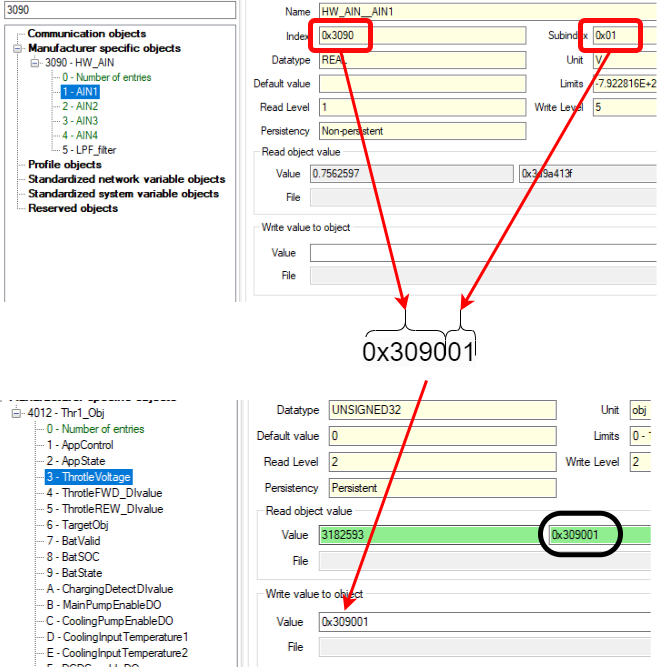

2.1.1. Configuring an object to be used in in the application (e.g. for Thr1_Obj__ThrottleVoltage)

All mapping of object to the application are done in the same way. For relays (digital outputs), switches (digital inputs), torque & velocity reference,... The main point is to show that you need to combine index and subindex of the object you want to use in your throttle application.

For example, to map the throttle voltage input to the emDrive analog input 1 (which has a CANOpen object HW_AIN_AIN1 with index 0x3090 and subindex 0x01 as shown in the picture bellow), you would write 0x309001 to Thr1_Obj__ThrottleVoltage.

To read if the correct value is written you need to use the HEX value (black circle).

3. How to Use Each Module

3.1 Initial Setup Assumptions

This document assumes that the angle sensor calibration has already been completed by the user, and that all other emDrive parameters for the motor and regulation have been properly configured. Before using any module we have to enable the CANOpen object Thr1_enable with index 0x4010 and subindex 0x00, for that we have to write 1 to the "value" field.

4010 - Thr1_enable = 1

3.2 Pre-charge Module

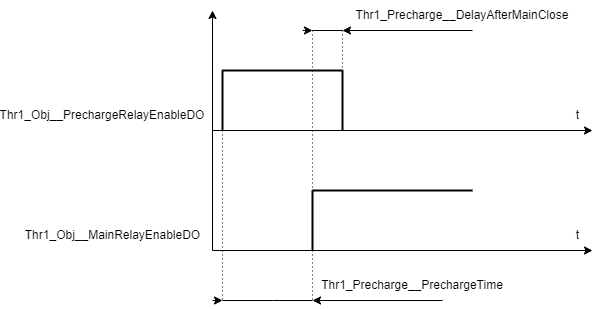

The Pre-charge module limits the charging current of the emDrive capacitors by activating the pre-charge relay switch before the main relay switch is engaged. The pre-charge relay switch has a resistor connected in series, which limits the current during the capacitor charging phase.

Note that the main and pre-charge relay switches are not integrated within the emDrive and must be provided externally. For more details, refer to section 5.4 of the EmDrive user manual.

For readability and clarity, the following abbreviations are used:

- The pre-charge relay switch refers to

Thr1_Obj__PrechargeRelayEnableDO - The main relay switch refers to

Thr1_Obj__MainRelayEnableDP

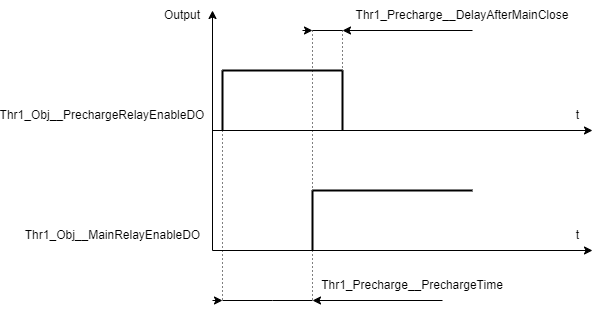

The sequence begins with the activation of the pre-charge relay switch. After the duration specified by the Thr1_Precharge__PrechargeTime parameter (default is 2 seconds), the drive voltage is checked. If the voltage does not exceed the threshold set by the Thr1_Precharge__MinDC_Voltage parameter, an error state is reported. If the voltage is above this threshold, the main relay switch is activated. Finally, after the time specified by the Thr1_Precharge__DelayAfterMainClose parameter has elapsed, the pre-charge relay switch is turned off, and the run state is set to true, activating the throttle and brake functionality. Additionally, we have a diagram illustrating the above functionality. It is assumed that after the pre-charge time, the DC voltage exceeds the set threshold, thus no error state is encountered.

To set this module you have to set all of the objects in table 3 and also use the correct mapping for Thr1_Obj__PrechargeRelayEnableDO and Thr1_Obj__MainRelayEnableDP.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Precharge__PrechargeTime | 0x4016 | 0x01 | Time to wait after pre-charge relay switch is activated before voltage is checked |

s |

| Thr1_Precharge__DelayAfterMainClose | 0x4016 | 0x02 | Time to wait before pre-charge relay switch is deactivated after the main relay switch has been activated |

s |

| Thr1_Precharge__MinDC_Voltage | 0x4016 | 0x03 | Minimum voltage that must be present on drive capacitors in order to not enter error state |

V |

Known bug:

Thr1_Precharge__DelayAfterMainClose: The name and description of this object in the configurator are incorrect.

The proper name should be: DelayAfterPrechargeOff.

The description should be: "After the Main relay is activated, we wait for the DelayAfterPrechargeOff time, then we deactivate the precharge relay."

You can also verify whether the pre-charge completed successfully or if an error occurred using the pre-charged module signals.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Precharge__Run | 0x4016 | 0x04 | Set to 1 when pre-charge is successfully finished | bit |

| Thr1_Precharge__Err | 0x4016 | 0x05 | Set to 1 if there was an error during pre-charge | bit |

3.2.1 Examples

- Pre-charge example 1

Description:

In this example, we will use the precharge module. For this, we need two relays: the main relay and the precharge relay. We also need to determine the voltage threshold for activating the main relay and the correct timings, which are described in Section 3.2.

Relay Connections

Main Relay: Connected to HW_LS1 = 0x30A0 0x02

Precharge Relay: Connected to HW_LS2 = 0x30A1 0x02

Voltage Measurement

The voltage will be measured using the inverter, which is the standard method (0x3101 0x07 Udc).

Timings

Precharge Time: 2 seconds

Time After Precharge Relay Turns Off: 0.5 seconds

Voltage Threshold

The voltage threshold for activating the main relay is 24V.

Objects to set:

-

- Enable Throttle Application:

0x4010 - Thr1_enable = 1 - Enable the Precharge Module:

Use the throttle general object0x4011 Thr1_Gento enable the proper module.0x4011 0x06 Precharge = 1 - Map Objects to the Application:

Choose the proper digital outputs to control the main relay and precharge relay:

e.g:

As per description we have the main relay connected to HW_LS1 and the precharge relay connected to HW_LS2. The object indexes are as follows:HW_LS1 = 0x30A0 0x02HW_LS2 = 0x30A1 0x02

We set the following:0x4012 0x14 MainRelayEnableDO = 0x30A0020x4012 0x15 PrechargeRelayEnableDO = 0x30A102

Voltage that is measured can be set but it is recommended to use default (0x3101 0x07 Udc), to change the object use the following:0x4012 0x16 PrechargeDC_Voltage = 0x310107

- Enable Throttle Application:

- Configure the Precharge Module:

Set the precharge time:0x4016 0x01 PrechargeTime = 2

Set the time after the precharge relay is turned off:0x4016 0x02 DelayAfterMainClose = 0.5

Set the minimum voltage that must be present:0x4016 0x03 MinDC_Voltage = 24 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

3.3 Throttle module

The throttle module is responsible for calculating the desired output torque based on the given input voltage. It provides features such as short to ground and short to power supply detection, reading forward and reverse switches, rate-limiting the output, and disabling the throttle when the brake is active. Below is a detailed guide on the state diagram and parameter settings for the throttle module.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Throtle__ZeroValue | 0x4013 |

0x01 |

At this input value output is zero. | V |

| Thr1_Throtle__ZeroDeadBand | 0x4013 | 0x02 | Defines how large zero dead band is | V |

| Thr1_Throtle__EnableDeadBand | 0x4013 | 0x03 | Defines how large enable dead band is. Should be lesser or equal to zero dead band. |

V |

| Thr1_Throtle__MaxInput | 0x4013 | 0x04 | At this input value output is at maximum value defined in Thr1_Throtle__OutFullPositive |

V |

| Thr1_Throtle__MinInput | 0x4013 | 0x05 | At this input value output is at minimum value defined in Thr1_Throtle__OutFullNegative |

V |

| Thr1_Throtle__NonValidMax | 0x4013 | 0x06 | Any input value grater then this will put throttle module into error state |

V |

| Thr1_Throtle__NonValidMin | 0x4013 | 0x07 | Any input value lesser than this will put throttle module into error state |

V |

| Thr1_Throtle__Progressive | 0x4013 | 0x08 | Determines how the output torque changes in relationship to the input between zero value and max value. |

/ |

| Thr1_Throtle__Invert | 0x4013 | 0x09 | Inverts output | Bit |

| Thr1_Throtle__RateLimit | 0x4013 | 0x0A | Limits how fast output can change. | 1/s |

| Thr1_Throtle__OutFullPositive | 0x4013 | 0x0B | Output when input reaches max input defined in Thr1_Throtle__MaxInput |

/ |

| Thr1_Throtle__OutFullNegative | 0x4013 | 0x0C | Output when input reaches min input defined in Thr1_Throtle__MinInput |

/ |

| Thr1_Throtle__DissableAtBrake | 0x4013 | 0x0D | If 1, throttle is disabled when brake is active. If 0 throttle and brake output are summed. |

Bit |

| Thr1_Throtle__WaitBeforeBridgeDisable | 0x4013 | 0x0E | How long to wait before bridge is disabled after bridge disable request is received. |

s |

| Thr1_Throtle__WaitAfterStart | 0x4013 | 0x0F | How long to wait after startup before operational state is entered |

s |

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Throtle__InVoltage | 0x4013 | 0x10 | Input signal | V |

| Thr1_Throtle__OutNorm | 0x4013 | 0x11 | Normed throttle output (-1 full negative, 1 full positive) |

/ |

| Thr1_Throtle__Out | 0x4013 | 0x12 | Output in system units | / |

| Thr1_Throtle__TotalOut | 0x4013 | 0x13 | Sum of outputs of throttle module and brake module |

/ |

| Thr1_Throtle__Enabled | 0x4013 | 0x14 | If 1 throttle is enabled | Bit |

| Thr1_Throtle__State | 0x4013 | 0x15 | Reports the state of throttle module. 1 -> Start, 2 -> WaitForNeutral, 3 -> Idle, 4 -> Driving, 5 -> Error, 6 -> Charging, 7 -> WaitForSpeedDrop, 8 -> WaitForSpeedDropChargingError, 9 -> ErrorEntry, 10 -> WaitForSpeedDropInit |

/ |

| Thr1_Throtle__Err | 0x4013 | 0x16 | If 1, throttle module is in error state | Bit |

| Thr1_Throtle__ErrCode | 0x4013 | 0x17 | Reports on error state of the entire Throttle application. 0x01 -> throttle error, 0x02 -> precharge error, 0x04 -> drive low level error, 0x08 -> brake error |

/ |

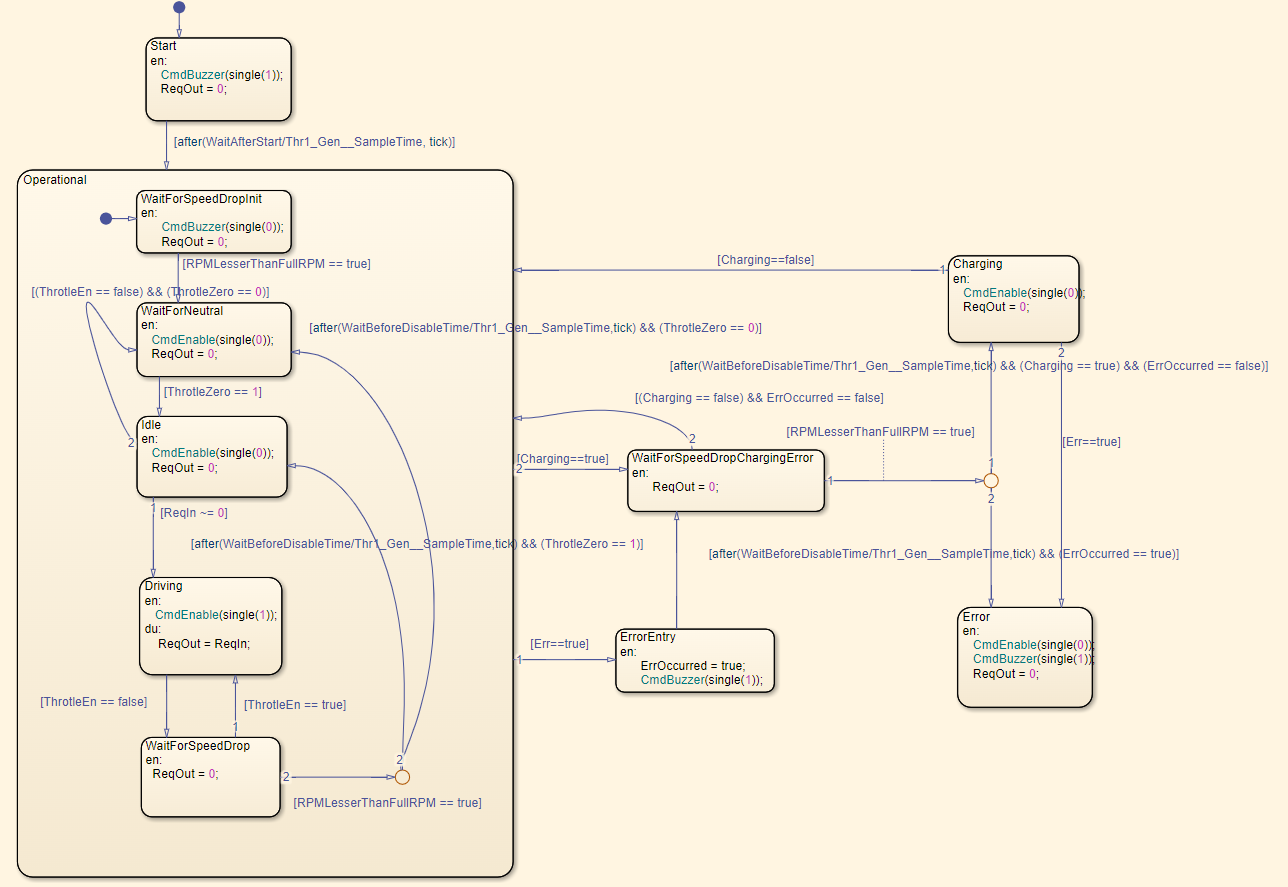

3.3.1 State Diagram

The state diagram for the throttle module consists of several states and transitions, ensuring the correct operation and safety of the system.

Startup State

- Buzzer Activation: Upon system start, the buzzer is activated if an external buzzer is connected.

- Wait Time: The system waits for the duration specified by the parameter Thr1_Timing__WaitAfterStart to complete the startup.

- Error Check: If an error is detected during startup, the system transitions directly to the Error State.

Operational State

- Buzzer Deactivation: The buzzer is disabled upon entering the operational state.

- RPM Check: The system waits for the RPM to drop to 0, if it is not already there.

- Bridge Disable: The bridge is disabled, and the system waits for the throttle to be set to zero.

Idle State

- Idle Mode: The system enters the Idle State, waiting for the input to move out of the zero position.

Driving State

- Throttle Enabled: If the input moves out of the zero position and the throttle is enabled, the system transitions to the Driving State.

- Bridge Enable: The bridge is enabled, and the output is forwarded to motor control.

WaitForNeutral State

- Throttle Disabled: If the throttle is disabled and the output moves out of the zero position, the system returns to the WaitForNeutral State.

WaitForSpeedDrop State

- Output Set to 0: When the throttle is disabled during the Driving State (either due to Thr1_Enable__Throttle being set to 0, input within the disable dead band, or outside allowed values), the system enters the WaitForSpeedDrop State.

- RPM Check: The output is set to 0, but the bridge remains enabled until the RPM drops below the value specified by Thr1_Brake__Full_RPM.

- Wait Time: The system waits for the time configured in Thr1_Timing__WaitBeforeBridgeDisable.

- State Transition: The state changes to Idle or WaitForNeutral based on whether the input is at zero or not.

Charging State

- RPM Drop: If charging is detected during the operational state, the system waits for the RPM to drop.

- Bridge Disable: The system moves to the Charging State, where the bridge is disabled.

- Return to Operational: When charging is no longer detected, the system returns to the operational state.

Error State

- Error Detection: If an error is detected in any state, the system transitions to the Error State.

- Bridge Disable: The bridge is disabled, and the buzzer is activated.

- RPM Check: In case of an error during the operational state, the system waits for the RPM to drop before disabling the bridge.

- Priority to Error State: If both charging and an error are detected simultaneously, the system prioritizes transitioning to the Error State.

- System Reset: There is no automatic recovery from the Error State; the system must be manually reset.

3.3.2 Input to Output Transformation

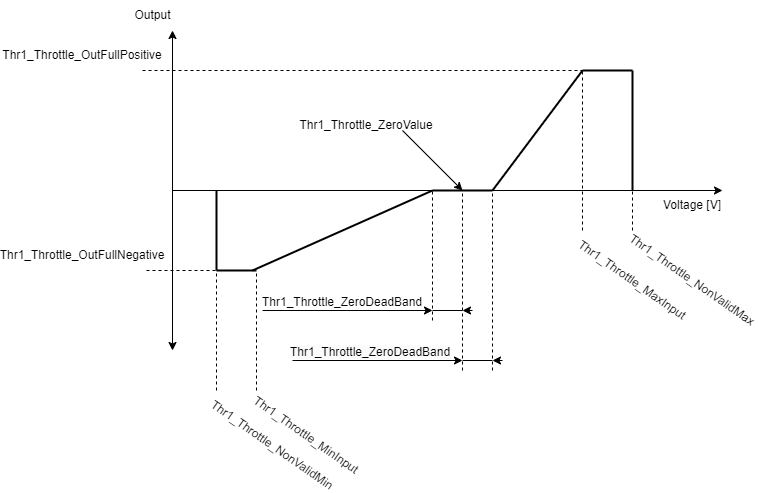

The input to output transformation converts the input voltage of the analog input to output torque, which is forwarded to motor control if the throttle is enabled. The basic transformation is illustrated in the graph below.

- Thr1_Throttle__ZeroValue: Defines the zero point of the input.

- Thr1_Throttle__ZeroDeadBand: Defines the dead band around the zero point. While the input voltage is within this dead band, the output remains zero.

- Thr1_Throttle__MinInput: Minimum valid input voltage.

- Thr1_Throttle__MaxInput: Maximum valid input voltage.

- Thr1_Throttle__OutFullPositive: Maximum positive output torque.

- Thr1_Throttle__OutFullNegative: Maximum negative output torque.

- Thr1_Throttle__NonValidMin: Minimum input voltage considered valid.

- Thr1_Throttle__NonValidMax: Maximum input voltage considered valid.

The transformation includes the following regions:

-

Zero Dead Band:

- Defined by

Thr1_Throttle__ZeroValueandThr1_Throttle__ZeroDeadBand. - Output remains zero when input voltage is within the dead band.

- Defined by

-

Positive Torque Region:

- From the end of the dead band to

Thr1_Throttle__MaxInput, the output rises in the positive direction from 0 toThr1_Throttle__OutFullPositive. - Output is calculated as , where is the normalized output (0 at 0 and 1 at

Thr1_Throttle__OutFullPositive), is the normalized input (0 at the edge of the dead band and 1 atThr1_Throttle__MaxInput), and is the parameterThr1_Throttle__Progressive, which ranges between 0.3 and 3. The default value for is 1, indicating a linear growth of output torque.

- From the end of the dead band to

-

Negative Torque Region:

- From the end of the dead band to

Thr1_Throttle__MinInput, the output falls in the negative direction. - Output is calculated as y=−∣x∣a

- From the end of the dead band to

-

Constant Max Torque Region:

- Between

Thr1_Throttle__MaxInputandThr1_Throttle__NonValidMax, the output remains at maximum positive torque. - Between

Thr1_Throttle__MinInputandThr1_Throttle__NonValidMin, the output remains at maximum negative torque. - If the input value increases beyond

Thr1_Throttle__NonValidMaxor decreases beyondThr1_Throttle__NonValidMin, the output torque is set to 0 and the throttle module enters the error state.

- Between

This transformation ensures that the throttle application accurately converts the input voltage into the appropriate output torque for motor control, with safeguards in place to handle invalid input values and prevent unintended behaviour.

3.3.3 Other throttle module functions

Enable dead band

Enable Dead Band functions similarly to Zero Dead Band. However, instead of setting the throttle output to 0, it disables the driver bridge when the input is less than a specified distance from the zero point. This distance is determined by the Enable Dead Band threshold. To disable Enable Dead Band, set its value to 0.

Ensure this threshold is always smaller than the Zero Dead Band threshold to prevent unusual behaviour.

Disable at brake

When the parameter 0x4013 0x0D DissableAtBrake is set to 1, the throttle module output is set to zero whenever the brake is active. This means that as soon as the brake is applied, the EmDrive system will start braking immediately, regardless of the throttle input.

When the parameter 0x4013 0x0D DissableAtBrake is set to 0, the throttle and brake outputs are combined before being sent to motor control. In this case, the EmDrive system will only start braking if the brake output is greater than the throttle output.

Rate limit

The rate limit controls how quickly the output can change in response to changes in the input (Higher the number, faster the change). This is determined by the parameter 0x4013 0x0A RateLimit.

When the input changes from 0 to 1 (works on normed value), the output will change from 0 to 1 in 1 / RateLimit seconds.

3.3.4 Examples

- Throttle example 1

Description:

Monodirectional throttle using only one analog input.

In this example, we will use a potentiometer as our throttle input. Our goal is to control the motor in velocity mode, ranging from 0 to 100 RPM.

Throttle Input Details

Potentiometer: Used as the throttle input. Connected to AIN3 = 0x3090 0x03

Voltage and RPM Control

Error Condition: If the voltage from the potentiometer is lower than 0.2V or higher than 4.8V, an error will occur (indicating a possible short or broken connection).

0 RPM: At 0.5V, the motor should run at 0 RPM.

100 RPM: At 4.5V, the motor should run at the maximum speed of 100 RPM.

Objects to set:

-

- Enable Throttle Application:

0x4010 - Thr1_enable = 1 - Enable the Throttle Module:

Use the throttle general object0x4011 Thr1_Gento enable the proper module.0x4011 0x03 Throtle = 1 - Map Objects to the Application:

Choose the reference value to control (velocity or torque) and map analog/digital inputs and outputs.

To control velocity:0x4012 0x06 TargetObj = 0x301005

To control torque:0x4012 0x06 TargetObj = 0x301004

Set the control mode (0 for torque, 1 for velocity):0x3100 0x01 ControlMode = 0 or 1

Define the analog throttle input (potentiometer on AIN3):0x4012 0x03 ThrottleVoltage = 0x309003 - Configure the Throttle Module:

Set the throttle voltage parameters as explained in Section 4.2:0x4013 0x01 ZeroValue = 0.50x4013 0x04 MaxInput = 4.50x4013 0x05 MinInput = 0.50x4013 0x06 NonValidMax = 4.80x4013 0x07 NonValidMin = 0.2

Set the maximum and minimum TorqueRef or VelocityRef:

In this example we will use max = 100rpm and min = 0rpm0x4013 0x0B OutFullPositive = 1000x4013 0x0C OutFullNegative = 0 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

- Enable Throttle Application:

- Throttle example 2

Description:

In this example, we will use the same potentiometer as in Throttle Example 1. The main difference is that this setup allows for bidirectional control of the throttle. Here’s how it works:

- At 2.5V, the motor will be at 0 RPM.

- At 4.5V, the motor will run at 100 RPM.

- At 0.5V, the motor will run at -100 RPM (in reverse).

This setup enables you to control the motor speed and direction using a single analog input.

Objects to set:

-

- Same as example "Throttle example 1"

- Same as example "Throttle example 1"

- Same as example "Throttle example 1"

- Configure the Throttle Module:

Set the throttle voltage parameters as explained in Section 4.2:0x4013 0x01 ZeroValue = 2.50x4013 0x04 MaxInput = 4.50x4013 0x05 MinInput = 0.50x4013 0x06 NonValidMax = 4.80x4013 0x07 NonValidMin = 0.2

Set the maximum and minimum TorqueRef or VelocityRef:

In this example we will use max = 100rpm and min = -100rpm0x4013 0x0B OutFullPositive = 1000x4013 0x0C OutFullNegative = -100

Additionaly we have to setIsNegativeBrake0x4013 0x10 IsNegativeBrake = 0 - Same as example "Throttle example 1"

- Throttle example 3

Description:

In this example, we will use the same potentiometer as in Throttle Example 1, along with two additional digital inputs to control the motor's direction.

Digital input 1 = 0x30B0 0x01 DIN1 - enable/disable positive throttle

Digital input 2 = 0x30B0 0x02 DIN2 - enable/disable negative throttle.

Objects to set:

-

- Same as example "Throttle example 1"

- Same as example "Throttle example 1"

- Same as example "Throttle example 1"

- Same as example "Throttle example 1"

Additionally, we only need to map digital input objects for enabling forward/reverse throttle.

e.g.

We will use object0x30B0 0x01 - DIN1to enable/disable positive throttle.

We will use object0x30B0 0x02 - DIN2to enable/disable negative throttle.

So we need to set:0x4012 0x04 ThrottleFWD_Dlvalue = 0x30b0010x4012 0x05 ThrottleREW_Dlvalue = 0x30b002

If DIN1 and DIN2 are the same value, the throttle will not work. Only one of them can be 1 and the other 0.

Currently the inverter does not support using only one physical input (e.g switch) to change direction. There must be two of them!

Additionaly we have to setIsNegativeBrake0x4013 0x10 IsNegativeBrake = 0 - Same as example "Throttle example 1"

3.4. Brake module

The brake module implements the brake function within the throttle application, operating similarly to the throttle module but with a crucial difference: it always outputs torque in the opposite direction of the current rotation and supports only monodirectional braking. The brake can be assigned to a different analog input or share the same analog input as the throttle module, beneficial for configurations where monodirectional throttle is used. In such cases, one direction from the zero point can manage throttle control while the other handles brake control.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Brake__ZeroValue | 0x4014 | 0x01 | At this input value output is zero. | V |

| Thr1_Brake__ZeroDeadBand | 0x4014 | 0x02 | Defines how large zero dead band is | V |

| Thr1_Brake__EnableDeadBand | 0x4014 | 0x03 | Defines how large enable dead band is. Should be lesser or equal to zero dead band. |

V |

| Thr1_Brake__MaxInput | 0x4014 | 0x04 | At this input value output is at maximum value |

V |

| Thr1_Brake__NonValidMax | 0x4014 | 0x05 | Any input value grater then this will put throttle module into error state. |

V |

| Thr1_Brake__NonValidMin | 0x4014 | 0x06 | Any input value lesser than this will put throttle module into error state. |

V |

| Thr1_Brake__Progressive | 0x4014 | 0x07 | Determines how the output torque changes in relationship to the input between zero value and max value. |

/ |

| Thr1_Brake__RateLimit | 0x4014 | 0x08 | Limits how fast output can change. Output can change from 0 to 1 in 1/Thr1_Brake__RateLimit s |

1/s |

| Thr1_Brake__OutFullPositive | 0x4014 | 0x09 | Output brake torque when input reaches max input. |

/ |

| Thr1_Brake__OutZero | 0x4014 | 0x0A | Output brake torque when input is at zero point. |

/ |

| Thr1_Brake__Full_RPM | 0x4014 | 0x0B | RPM below which brake torque is scaled towards 0. |

/ |

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Brake__InVoltage | 0x4014 | 0x0C | Input signal | V |

| Thr1_Brake__OutNorm | 0x4014 | 0x0D | Normed brake output (-1 full negative, 1 full positive) |

/ |

| Thr1_Brake__Out | 0x4014 | 0x0E | Output in system units | / |

| Thr1_Brake__Enabled | 0x4014 | 0x0F | If 1 brake is enabled | Bit |

| Thr1_Brake__Err | 0x4014 | 0x10 | Brake error state |

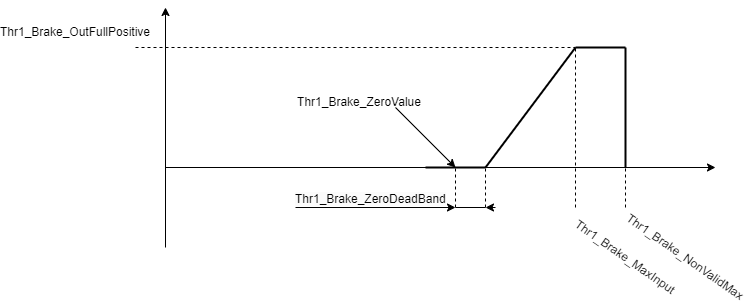

3.4.1 Input to Output Transformation

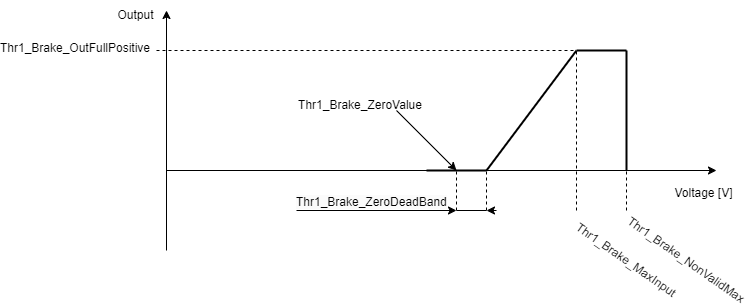

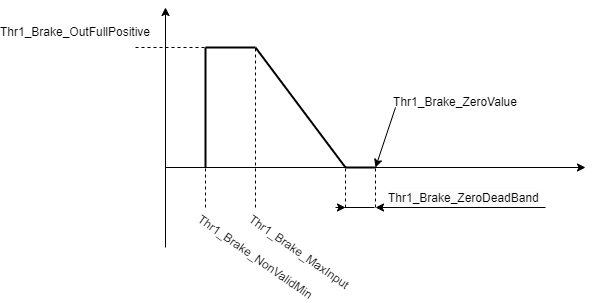

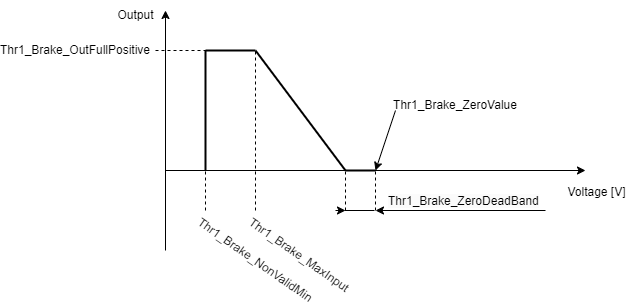

The input to output transformation functions in a similar manner to the input-output transformation of the throttle module. A typical example of this transformation is illustrated in the picture below.

The type of slope between the end of the zero dead band and Thr1_Brake__MaxInput is determined by the parameter Thr1_Brake__Progressive, similar to how it is for the throttle module. Additionally, the brake module can be configured to increase brake torque when the input decreases. This can be achieved by setting the parameter Thr1_Brake__MaxInput to a value smaller than Thr1_Brake__ZeroValue. The resulting input to output transformation for this configuration is illustrated in the picture below.

For both modes, it is essential to configure the parameters Thr1_Brake__NonValidMax and Thr1_Brake__NonValidMin. Failing to do so will result in incorrect operation of the short to ground and short to power supply error detection.

3.4.2 Examples

To use the brake module, you first need to configure the throttle module and ensure it works as expected.

- Brake example 1

Description:

Monodirectional throttle & brake using only one analog input.

In this example, a potentiometer is used to adjust voltage from 0V to 5V. The operational range is 0.2V to 4.8V. If the voltage goes outside this range, an error occurs.

Throttle and Brake Operation

Neutral Position: At 2.5V, the motor is in neutral.

Increasing Voltage: Raising the voltage above 2.5V speeds up the motor.

Decreasing Voltage: Lowering the voltage below 2.5V brakes the motor.

Before proceeding with this example, ensure you have completed and prepared a working setup of "Throttle Example 1" with torque control, not velocity. To achieve this, configure the following settings:

- Set Target Object:

0x4012 0x06 TargetObj = 0x301004 - Set Control Mode:

0x3100 0x01 ControlMode = 0

Objects to set:

- Enable Throttle Application:

0x4010 - Thr1_enable = 1 - Enable the Throttle & Brake Module:

0x4011 0x03 Throtle = 10x4011 0x04 Brake = 1 - Map Objects to the Application:

Torque control0x4012 0x06 TargetObj = 0x301004

Check that torque mode is active if not set it with control mode = 0:0x3100 0x01 ControlMode = 0

Define the analog throttle input (e.g., potentiometer on AIN3):0x4012 0x03 ThrotleVoltage = 0x309003

Define the analog brake input (same as ThrotleVoltage in this example):0x4012 0x12 BrakeVoltage = 0x309003 - Configure the Throttle Module:

Set the throttle voltage parameters as explained in Section 4.2:0x4013 0x01 ZeroValue = 2.50x4013 0x04 MaxInput = 4.50x4013 0x05 MinInput = 0.50x4013 0x06 NonValidMax = 4.80x4013 0x07 NonValidMin = 0.2

Set the maximum and minimum TorqueRef

In this example we will use max = 10Nm and min = 0Nm (if there is no load) - BIDIRECTIONAL throttle must be dissabled (one of these must be 0) for using only one analog input as throttle and brake.0x4013 0x05 OutFullPositive = 100x4013 0x05 OutFullNegative = 0 - Configure the Brake Module:

Set the brake voltage parameters:0x4014 0x01 ZeroValue = 2.50x4014 0x04 MaxInput = 0.50x4014 0x05 NonValidMax = 4.80x4014 0x06 NonValidMin = 0.20x4014 0x09 OutFullPositive = 10 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

- Brake example 2

Description:

In this example, we will use two analog inputs to control the motor:

- Analog Input 1: Controls the throttle (motor speed).

- Analog Input 2: Controls the brake.

This setup allows you to manage both the acceleration and deceleration of the motor independently using separate analog inputs.

Objects to set:

- Same as "Brake example 1"

- Same as "Brake example 1"

- Map Objects to the Application:

Torque control0x4012 0x06 TargetObj = 0x301004

Check that torque mode is active if not set it with control mode = 0:0x3100 0x01 ControlMode = 0

Define the analog throttle input (e.g., potentiometer on AIN3):0x4012 0x03 ThrotleVoltage = 0x309003

Define the analog brake input (e.g., potentiometer AIN2):0x4012 0x12 BrakeVoltage = 0x309002 - Configure the Throttle Module:

Set the throttle voltage parameters as explained in Section 4.2:0x4013 0x01 ZeroValue = 0.50x4013 0x04 MaxInput = 4.50x4013 0x05 MinInput = 0.50x4013 0x06 NonValidMax = 4.80x4013 0x07 NonValidMin = 0.2

Set the maximum and minimum TorqueRef

In this example we will use max = 10Nm and min = 0Nm (if there is no load) - BIDIRECTIONAL throttle must be dissabled (one of these must be 0) for using only one analog input as throttle and brake.0x4013 0x05 OutFullPositive = 100x4013 0x05 OutFullNegative = 0 - Configure the Brake Module:

Set the brake voltage parameters:0x4014 0x01 ZeroValue = 0.50x4014 0x04 MaxInput = 4.50x4014 0x05 NonValidMax = 4.80x4014 0x06 NonValidMin = 0.20x4014 0x09 OutFullPositive = 10 - Same as "Brake example 1"

3.5. Pump control module

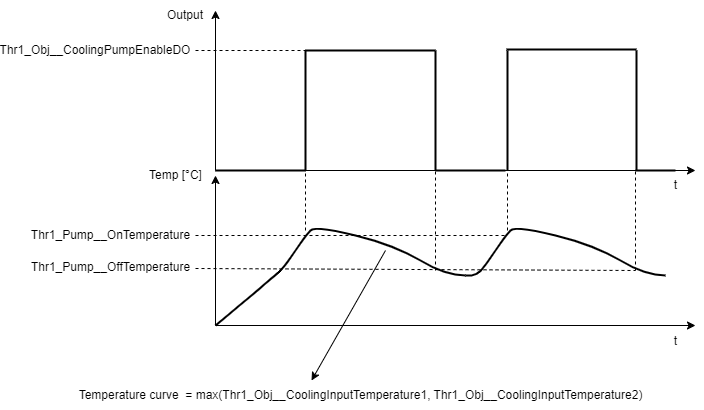

The Pump Control Module manages the operation of two pumps in the system: the main pump and the cooling pump.

- The main pump is activated whenever the throttle application is in the run state or when the cooling pump is active.

- The cooling pump is regulated by a simple hysteresis controller.

Activation: The cooling pump turns on if the temperature exceeds the threshold set in the Thr1_Pump__OnTemperature parameter.

Deactivation: The cooling pump turns off if the temperature drops below the threshold set in the Thr1_Pump__OffTemperature parameter.

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Pump__OnTemperature | 0x4015 | 0x01 | High threshold temperature | °C |

| Thr1_Pump__OFFTemperature | 0x4015 | 0x02 | Low threshold temperature | °C |

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Pump__InTemperature | 0x4015 | 0x03 | The temperature of the higher of the mapped temperatures |

°C |

3.5.3 Examples

- Pump example 1

Description:

In this example we will control two pumps: main pump and cooling pump.

Main pump on LS3 0x30A2 0x02 Value

Cooling pump on LS4 0x30A3 0x02 Value

Temperature at which we start the pump = 50 °C

Temperature at which we stop the pump = 60 °C

Objects to set:

- Enable Throttle Application:

0x4010 - Thr1_enable = 1 - Enable the Pump Module:

0x4011 0x05 Pump = 1 - Map Objects to the Application:

For this module theCoolingInputTemperature1andCoolingInputTemperature2are set by default.Ctrl_Bridge__StatusHeatsinkTempis mapped toCoolingInputTemperature1Ctrl_Gen_Stat__MotorSensorTempis mapped toCoolingInputTemperature20x4012 0x0D CoolingInputTemperature1 = 0x31CE000x4012 0x0E CoolingInputTemperature2 = 0x31010A

Next we need to map the digital outputs where our pumps are connected to. In this example we will use:

Main pump on LS30x30A2 0x02 Value

Cooling pump on LS40x30A3 0x02 Value0x4012 0x0B MainPumpEnableDO = 0x30A2020x4012 0x0C CoolingPumpEnableDO = 0x30A302 - Configure the Pump Module:

Set the temperature at which the pump starts and stops.0x4015 0x01 OnTemperature = 600x4015 0x02 OffTemperature = 50 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

3.6. DC-DC turn on delay module

DC-DC turn on delay module enables an external DC-DC module with a delay after start-up. The delay time

can be configured by setting parameter Thr1_DCDC__StartupDelay

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_DCDC__StartupDelay | 0x4017 | 0x00 | Delay time after which external DC-DC module is turned on | s |

3.6.1 Examples

- DC-DC delay example 1

The relay is connected to LS2 0x30A1 0x02 Value

DC-DC turn on delay set to 5s.

Objects to set:

- Enable Throttle Application:

0x4010 - Thr1_enable = 1 - Enable the DC-DC Module:

0x4011 0x07 DC_DC = 1 - Map Objects to the Application:

DC-DC relay is on LS20x30A1 0x02 Value0x4012 0x0F DCDCenableDO = 0x30A102 - Configure the DC-DC Module:

Set the delay to 5s0x4017 0x00 Thr1_DCDC__StartupDelay = 5 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

3.7. SOC monitoring and charging detection module

The SOC (State of Charge) monitoring module and the charging detection module are implemented together due to their similarities. However, both modules can be enabled and disabled independently. SOC monitoring requires a Battery Management System (BMS) to detect SOC. Note that the BMS is not included in the emDrive. If SOC monitoring is needed, an independent BMS must be connected to the CAN bus.

3.7.1 SOC Monitoring Module

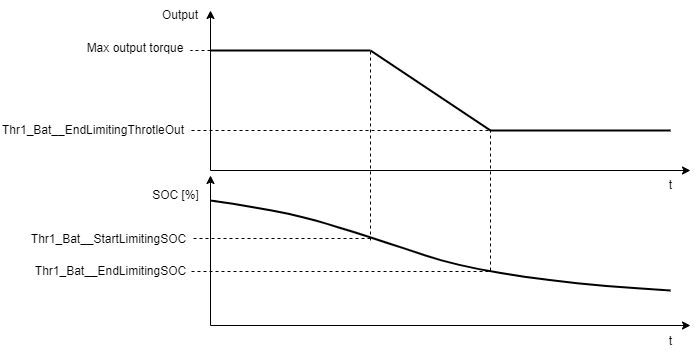

The SOC monitoring module tracks the SOC state as reported by the BMS.

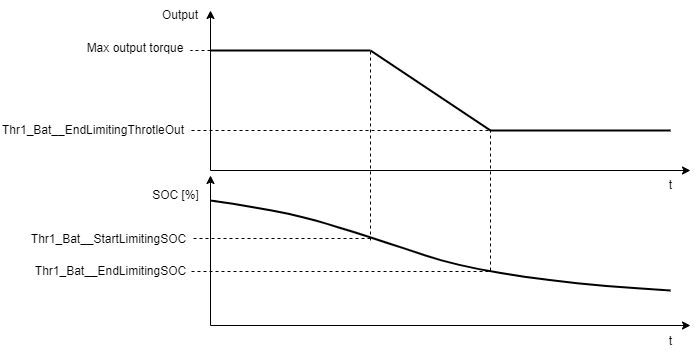

-

Behaviour:

- If SOC drops below the level specified by the parameter

Thr1_Bat__StartLimitingSOC, the module will start limiting the maximum output torque. - If SOC falls below the level specified by

Thr1_Bat__EndLimitingSOC, the maximum torque output will be set to the value given inThr1_Bat__EndLimitingThrottleOut. - When SOC is between

Thr1_Bat__StartLimitingSOCandThr1_Bat__EndLimitingSOC, the maximum torque is linearly reduced. The reduction goes from the maximum torque (as defined in the throttle module) atThr1_Bat__StartLimitingSOCto the torque defined inThr1_Bat__EndLimitingThrottleOutatThr1_Bat__EndLimitingSOC.

- If SOC drops below the level specified by the parameter

-

Throttle Limiting Speed:

- Controlled by the parameter

Thr1_Bat__ThrottleLimitRamp. - The limiting speed functions similarly to rate limiting in the throttle and brake modules, where throttle limiting can range from 0 to 1 in

1/Thr1_Bat__ThrottleLimitRampseconds.

- Controlled by the parameter

3.7.2 Charging detection Module

The charging detection module monitors whether the battery is being charged and reports this status to the throttle module.

- Behaviour::

- If a BMS is present, the module queries the BMS to check if the battery is currently being charged.

- Alternatively, the module can observe the state of the input mapped to the parameter

Thr1_Obj__ChargingDetectDIvalue:- If the value is 1, the battery is considered to be charging.

- If the value is 0, the battery is considered to be not charging.

This setup allows for accurate monitoring and management of the battery's state of charge and charging status, ensuring optimal performance and safety.

3.7.3 Parameters and signals overview

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Bat__StartLimitingSOC | 0x4018 | 0x01 | SOC percentage at which throttle limiting starts. | % |

| Thr1_Bat__EndLimitingSOC | 0x4018 | 0x02 | SOC percentage at which throttle limiting is at maximum |

% |

| Thr1_Bat__EndLimitingThrotleOut | 0x4018 | 0x03 | Maximum torque output when throttle limiting is at maximum. |

/ |

| Thr1_Bat__ThrotleLimitRamp | 0x4018 | 0x04 | Limits how fast throttle limiting can change. | 1/s |

| Object Name |

Object Index |

Object Subindex |

Description | Unit |

| Thr1_Bat__Valid | 0x4018 | 0x05 | If 0, no BMS is available | / |

| Thr1_Bat__SOC | 0x4018 | 0x06 | Battery SOC in percentage | % |

| Thr1_Bat__LimitThrotle | 0x4018 | 0x07 | Current throttle limit in system units | / |

| Thr1_Bat__LimitNorm | 0x4018 | 0x08 | Normed current throttle limit. (1 -> no limiting, 0 -> maximum allowed limit) |

/ |

| Thr1_Bat__Charging | 0x4018 | 0x09 | If 1, charging is detected. If 0 charging is not detected. |

Bit |

3.7.4 Examples

- SOC example 1

Description:

In this example we first need a working example of Throttle module to control torque. (It is also possible to control velocity.)

Next we need the following values:

- Battery (BMS) calie/present

- SOC in percent

To achive this we can use the PDOs to get the values - in this example we will assume that we get the upper values via CAN and we set the values to our 0x2051 Customer_Data_16bit__Value. How to configure the PDOs refer to the user manual section 9.4-Data transfer – Process Data Object (PDO).

Battery (BMS) calie/present needs to be higher than 0, otherwise inverter thinks there is no BMS.

0x2051 0x01 Customer_Data_16bit__Value1 = Battery (BMS) calie/present (needs to be higher than 0)

0x2051 0x02 Customer_Data_16bit__Value2 = SOC in percent

We will start limiting the output when the battery has SOC = 10%

We will limit the output with a ramp of value 0.01 until we reach SOC = 5%, after which we stay at value 10Nm (in case of velocity control the unit of this value will be in PRM - 10RPM).

Objects to set:

-

- Enable the SOC Module:

Use the throttle general object0x4011 Thr1_Gento enable the proper module.0x4011 0x08 SOC = 1 - Map Objects to the Application:

As mentioned above we have the required date on the Costomer_Data_16bit_Values.Customer_Data_16bit__Value1 = 0x2051 0x01Customer_Data_16bit__Value2 = 0x2051 0x02

We set the following:0x4012 0x07 BatValid = 0x2051010x4012 0x08 BatSOC = 0x205102

- Enable the SOC Module:

- Configure the SOC Module:

Set at what SOC percent we start limiting the output (at 10 %):0x4018 0x01 StartLimitingSOC = 10

Set at what SOC percent we stop limiting the output (at 5 %):0x4018 0x02 EndLimitingSOC = 5

Set what will the max value output be at the valueEndLimitingSOC(10Nm):0x4018 0x03 EndLimitingThrotleOut = 10

Set the ramp parameter for slope:0x4018 0x04 ThrotleLimitRamp = 0.01 - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

- Charging detection example 2

Description:

You need a working throttle example.

As mentioned above we can detect charging with the state that is reported by BMS for that we need to get the state of the BMS in this example we will use method as in SOC example 1, where use the PDOs and save the state to Costomer_Data_16bit_Value.Customer_Data_16bit__Value1 = 0x2051 0x01 = Battery (BMS) calie/present (needs to be higher than 0)Customer_Data_16bit__Value3 = 0x2051 0x03 = State of BMS

Objects to set:

-

- Enable the SOCModule and ChargingDetect Module:

Use the throttle general object0x4011 Thr1_Gento enable the proper module.0x4011 0x08 SOC = 10x4011 0x09 ChargingDetect = 1 - Map Objects to the Application:

As mentioned above we have the required date on the Costomer_Data_16bit_Values.Customer_Data_16bit__Value1 = 0x2051 0x01Customer_Data_16bit__Value3 = 0x2051 0x03

We set the following:0x4012 0x07 BatValid = 0x2051010x4012 0x09 BatState = 0x205103

- Enable the SOCModule and ChargingDetect Module:

- Configure the ChargingDetect Module:

With this module there is no other configuration needed. If the value onCustomer_Data_16bit__Value3== (charge = 4) or (charge_done = 5) -> driving is disabled. - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1

- Charging detection example 3

Description:

You need a working throttle example.

The next method is to detect charging with a digital input, for that we will use digital input 4.

0x30B0 0x04 DIN4

Objects to set:

-

- Enable the SOCModule and ChargingDetect Module:

Use the throttle general object0x4011 Thr1_Gento enable the proper module.0x4011 0x08 SOC = 10x4011 0x09 ChargingDetect = 1 - Map Objects to the Application:

As mentioned above we have the required date on the Costomer_Data_16bit_Values.Customer_Data_16bit__Value1 = 0x2051 0x01DIN4 = 0x30B0 0x04

We set the following:0x4012 0x07 BatValid = 0x2051010x4012 0x0A ChargingDetectDlvalue = 0x30B004

- Enable the SOCModule and ChargingDetect Module:

- Configure the ChargingDetect Module:

With this module there is no other configuration needed. If the value of DIN4 == 1 -> driving is disabled. - Save and Reset:

Save the settings (Ctrl+S) and perform a reset.

Switch to operational mode.

Test

Enable auto start if everything works correctly (inverter will always go to operational mode after reset).0x3000 0x03 AutoStart = 1