emDrive User Manual

- Scripting

- Parameters

- Access Level

- Lua Manual

- Throttle Application Manual

- Interfacing To Inverter using Python and Peak CAN Interface

- Software Firmware Update Procedure

- Lua Manual

Scripting

This page is still under construction, some information may be incomplete.

Introduction

The emDrive Configurator scripting feature lets you create custom C# (.cs) scripts to communicate with CAN Open devices. Scripts can be run in a dedicated Script Window within the application. You can perform actions such as reading and writing device parameters (SDO operations), sending direct commands, managing device states via NMT commands, and even logging or displaying messages. This guide explains the basics—from script file creation to using the scripting API for simple operations.

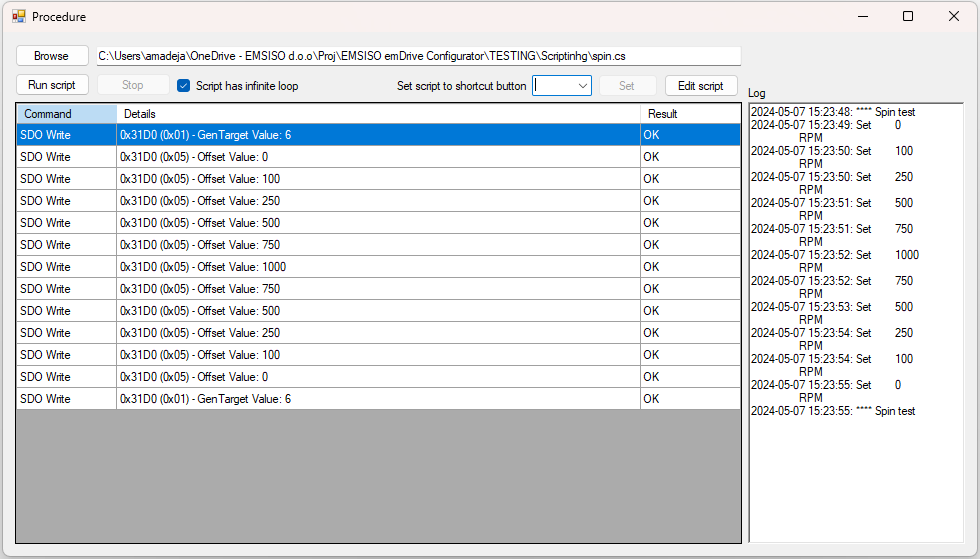

User Interface Overview

When you open the Script Window (via Device > Script), you will see several controls:

Long-running scripts cannot be used with Shortcuts.

Creating a Script File

All scripts must be written in C#. You can use any text editor or an IDE like Visual Studio Code to create a .cs file. Two common templates are provided:

Basic Template

For quick scripts without long-running loops, use a template similar to this:

using System;

using emDrive_Configurator; // or "using eDrive_Configurator;" for versions 2.5.4.0 and lower

public class Script

{

public void Main()

{

// Your code here (e.g., SDO read/write, logging, etc.)

Procedure.Log("Hello from the basic script!");

}

}Version 2.5.4.0 and lower use using eDrive_Configurator; instead of using emDrive_Configurator;.

Long-Running Template (Infinite or Looping Scripts)

For scripts that must run continuously (e.g., monitoring sensor values), change the Main method to accept a CancellationToken. This lets the tool cancel your loop when you click Stop.

This feature is available only from version 2.9.0.0 and onwards. Long-running scripts should not be used in versions below 2.9.0.0.

using System;

using System.Threading;

using emDrive_Configurator; // or "using eDrive_Configurator;" for versions 2.5.4.0 and lower

public class Script

{

public void Main(CancellationToken cancellationToken)

{

while (!cancellationToken.IsCancellationRequested)

{

// Periodically execute code (e.g., monitor sensor value)

Procedure.Log("Script running...");

Procedure.Delay(1000); // Pause for one second

}

Procedure.Log("Script canceled.");

}

}Ensure you include using System.Threading; if you are using long-running loops with a cancellation token. (Version 2.9.0.0 and later support this feature.)

Scripting API Methods

The emDrive Configurator exposes several API methods that you can use in your scripts. Below is a detailed summary of the methods available for interacting with your CAN Open device.

Every method needs to be called using the Procedure class as seen in the examples above.

SDO Data Transfers

SDO_Read Methods

These methods read data (Service Data Objects) from the device. They come in several overloads:

bool SDO_Read(int nodeId, uint index, ushort subindex, out object value, out string errMessage);Usage: Reads a parameter from a specified node and object index/subindex. The method converts the device’s hex response into a readable value and returns any error messages if the read fails.

dynamic SDO_Read(int NodeId, uint Index, ushort Subindex);Usage: Returns the read value as a dynamic type after automatically processing the hex data.

bool SDO_Read(int NodeId, uint Index, ushort Subindex, Action<CO_Object, dynamic> Parser);Usage: Reads data and passes the value to a provided callback (Parser) for further processing.

SDO_Write Methods

These methods write a value to a CAN Open object.

bool SDO_Write(int nodeId, uint index, ushort subindex, dynamic value, out string errMessage);Usage: Writes the specified value to a node’s object. It logs the operation and returns a message indicating success or error.

Direct Command Execution

string Direct_Command(string text);Usage: Sends a direct command (as a simple string) to the device and returns the response.

This is recommended only for advanced users who are familiar with the CAN Open protocol on the EMSISO CAN Card

Timing Control

void Delay(int Duration);Usage: A simple wrapper around Thread.Sleep that pauses script execution. The duration is in milliseconds.

Network Management (NMT) Commands

These methods allow you to change the state of CAN Open nodes:

bool NMT_Operational();

bool NMT_Operational(int nodeId);Usage: Switch the device (or a specific node) to Operational Mode.

bool NMT_Preoperational();

bool NMT_Preoperational(int nodeId);Usage: Set the device (or node) into Preoperational Mode.

bool NMT_Stopped();

bool NMT_Stopped(int nodeId);Usage: Stops the device (or node).

bool NMT_Reset();

bool NMT_Reset(int nodeId);

bool NMT_Reset_Communication();

bool NMT_Reset_Communication(int nodeId);Usage: Resets the device or its communication link.

User Interaction and Logging

void ShowMessagebox(string text);Usage: Display a standard message box to the user.

bool ShowDialog(string text);Usage: Open a dialog window that returns a Boolean value (for example, after the user confirms an action).

dynamic InputDialog(string caption);Usage: Shows a prompt for user input and returns the entered text.

Script Examples

Below are two example scripts that illustrate how to use the API methods to interact with CAN Open devices.

Example 1: Basic SDO Read/Write

This example shows how to read a value from a CAN Open object and then write a new temporary value.

using System;

using emDrive_Configurator;

public class Script

{

public void Main()

{

// Define node and object identifiers (using temporary indexes)

int nodeId = 1;

uint index = 0x2000;

ushort subindex = 0x01;

object readValue;

string errMessage;

// Attempt to read the current value from the device

if (Procedure.SDO_Read(nodeId, index, subindex, out readValue, out errMessage))

{

Procedure.Log("SDO Read successful. Value: " + readValue);

}

else

{

Procedure.Log("SDO Read error: " + errMessage);

}

// Set a temporary value and write it to the device

dynamic tempValue = 123; // Change 123 to any temporary test value as needed

if (Procedure.SDO_Write(nodeId, index, subindex, tempValue, out errMessage))

{

Procedure.Log("SDO Write successful. New Value: " + tempValue);

}

else

{

Procedure.Log("SDO Write error: " + errMessage);

}

}

}Example 2: Test with Long-Running Loop

This script continuously reads from the device and exits the loop if a defined break condition is met. It demonstrates the use of a CancellationToken so that the script can be stopped via the UI.

using System;

using System.Threading;

using emDrive_Configurator;

public class Script

{

// Use this template for scripts with long-running loops.

public void Main(CancellationToken cancellationToken)

{

int nodeId = 1;

uint index = 0x2000;

ushort subindex = 0x01;

int condition = 20;

while (!cancellationToken.IsCancellationRequested)

{

dynamic? value;

string errMessage;

if (Procedure.SDO_Read(nodeId, index, subindex, out value, out errMessage))

{

Procedure.Log("Current SDO Value: " + value);

}

else

{

Procedure.Log("Read error: " + errMessage);

}

// Check if a break condition is met (example: value equals a specific test value)

if (value is int && value == condition)

{

Procedure.Log("Break condition met. Exiting loop.");

break;

}

// Wait for 1 second before next iteration

Procedure.Delay(1000);

}

Procedure.Log("Script execution completed.");

}

}Advanced Scripting

Script-Watch Interoperability

This functionality is only available for emDrive Configurator 2.13.0.0 and later.

These API calls allow the user to add virtual script objects to Watch and write to them, as well as request the last value read for a specific object already in Watch. This can be achieved by using the WatchScriptObject class or the method calls described below.

WatchScriptObject class

The WatchScriptObject class uses the API calls described below but is a more user-friendly approach to this functionality. Unless specified the index and subindex properties will be set automatically. index will always be 0xFFFF and subindex will increment from 0 onwards. If the user wishes to reset the subindex counter they must call the ResetSubIndexCounter method.

public class WatchScriptObject

{

// Properties

public string Name { get; }

public int NodeId { get; } // Default: 0

public uint Index { get; } // Default: 0xFFFF

public ushort SubIndex { get; }

public ushort DataType { get; }

// Constructors

public WatchScriptObject(string name, ushort datatype);

public WatchScriptObject(string name, ushort subindex, ushort datatype);

public WatchScriptObject(string name, uint index, ushort subindex, ushort datatype);

// Methods

public bool TryToAddToWatch();

public bool TryToAddValueToWatch(dynamic value);

}The TryToAddToWatch method will attempt to add the virtual object to Watch. See TryAddScriptEntryToWatch method for possible errors.

The TryToAddValueToWatch method will attempt to add the value to the already created virtual object in Watch. See TryAddScriptEntryValue method for possible errors.

TryAddScriptEntryToWatch method

Attempts to create a new script virtual object in Watch with the specified name, nodeId, index, subindex, and datatype. Returns true if successful or false if failed.

public static bool TryAddScriptEntryToWatch(string name, int nodeId, uint index, ushort subindex, ushort datatype)Fail reasons:

- Object with specified

nodeId,indexandsubindexalready exists in Watch.

TryAddScriptEntryValue method

Attempts to write value to the script virtual object in Watch. Returns true if successful or false if failed.

public static bool TryAddScriptEntryValue(int nodeId, uint index, ushort subindex, dynamic value)Fail reasons:

- Object with specified

nodeId,indexandsubindexdoes not exist in Watch. - Failed to convert value to the declared datatype.

TryGetLastWatchValue method

Attempts to get the last read value of the object specified with nodeId, index, subindex and saves it to value. Returns true if successful or false if failed.

public static bool TryGetWatchValue(int nodeId, uint index, ushort subindex, out double value)Fail reasons:

- Object with specified

nodeId,indexandsubindexdoes not exist in Watch. - Failed to convert object value to type

double.

Example file

Example file for Script - Watch Interoperability (also available as download)

/*

Author: Amadej Arnus

Date: 2024-04-23

*/

using System;

using System.Windows.Forms;

using emDrive_Configurator;

using System.Threading;

using Timer = System.Threading.Timer;

using System.Collections.Generic;

using System.Diagnostics;

using System.Drawing;

using System.Globalization;

using System.IO;

using System.IO.Ports;

using System.Linq;

using System.Management;

using System.Text;

using System.Text.RegularExpressions;

public class Script

{

// Prepare error string

string err = string.Empty;

// Create object that we will attempt to read from watch

CO_Object HwMonitorUdc = new CO_Object(0x3071, 0x00);

public void Main(CancellationToken cancellationToken)

{

// This will run the example for the WatchScriptObject

ObjectBasedVersion(cancellationToken);

// This will run the example for the API calls

//ObjectBasedVersion(cancellationToken);

}

private void ObjectBasedVersion(CancellationToken cancellationToken)

{

// Create new objects for watch-script interoperability

Procedure.WatchScriptObject intObject = new Procedure.WatchScriptObject("ScriptObject_Int32", 0x0004);

Procedure.WatchScriptObject floatObject = new Procedure.WatchScriptObject("ScriptObject_Real32", 0x0008);

// Add int object to watch

if (intObject.TryToAddToWatch())

{

LogResult("ScriptObject_Int32 added to watch");

}

else

{

LogResult("ScriptObject_Int32 not added to watch");

}

// Add float object to watch

if (floatObject.TryToAddToWatch())

{

LogResult("ScriptObject_Real32 added to watch");

}

else

{

LogResult("ScriptObject_Real32 not added to watch");

}

int i = 0;

// Do the loop until cancellationToken is requested

while (!cancellationToken.IsCancellationRequested)

{

double hwMonitorValue = 0;

// Read last value of HwMonitorUdc object

if (HwMonitorUdc.TryGetWatchValue(1, out hwMonitorValue))

{

i++;

// Set new value to int and float objects

if (!intObject.TryToAddValueToWatch(i))

{

LogResult("Failed to write value to ScriptObject_Int32");

}

if (!floatObject.TryToAddValueToWatch(hwMonitorValue * 1.5))

{

LogResult("Failed to write value to ScriptObject_Real32");

}

}

// If not successful, log the error

else

{

LogResult("Failed to get HwMonitorUdc value");

}

Procedure.Delay(200);

}

}

private void ApiBasedVersion(CancellationToken cancellationToken)

{

// Add int object to watch

if (TryAddScriptEntryToWatch("ScriptObject_Int32", 1, 0xFFFF, 0x01, datatype: 0x0004))

{

LogResult("ScriptObject_Int32 added to watch");

}

else

{

LogResult("ScriptObject_Int32 not added to watch");

}

// Add float object to watch

if (TryAddScriptEntryToWatch("ScriptObject_Real32", 1, 0xFFFF, 0x02, datatype: 0x0008))

{

LogResult("ScriptObject_Real32 added to watch");

}

else

{

LogResult("ScriptObject_Real32 not added to watch");

}

int i = 0;

// Do the loop until cancellationToken is requested

while (!cancellationToken.IsCancellationRequested)

{

double hwMinutorValue = 0;

// Read last value of HwMonitorUdc object

if (TryGetWatchValue(1, 0x3071, 0x00, out hwMinutorValue))

{

i++;

// Set new value to int and float objects

if (!TryAddScriptEntryValue(1, 0xFFFF, 0x01, i))

{

LogResult("Failed to write value to ScriptObject_Int32");

}

if (!TryAddScriptEntryValue(1, 0xFFFF, 0x02, hwMinutorValue * 1.5))

{

LogResult("Failed to write value to ScriptObject_Real32");

}

}

// If not successful, log the error

else

{

LogResult("Failed to get HwMonitorUdc value");

}

Procedure.Delay(200);

}

}

// The following methods are just wrappers to shorten the method calls

bool TryAddScriptEntryToWatch(string name, int nodeId, uint index, ushort subindex, ushort datatype)

{

return Procedure.TryAddScriptEntryToWatch(name, nodeId, index, subindex, datatype);

}

bool TryAddScriptEntryValue(int nodeId, uint index, ushort subindex, dynamic value)

{

return Procedure.TryAddScriptEntryValue(nodeId, index, subindex, value);

}

bool TryGetWatchValue(int nodeId, uint index, ushort subindex, out double value)

{

return Procedure.TryGetWatchValue(nodeId, index, subindex, out value);

}

void LogResult(string LogString)

{

LogString = DateTime.Now.ToString("yyyy-MM-dd HH:mm:ss") + ": " + LogString;

Procedure.Log(LogString);

}

}

// CO_Object for readability

class CO_Object

{

public uint index;

public ushort subindex;

public dynamic value;

public CO_Object(uint index, ushort subindex)

{

this.index = index;

this.subindex = subindex;

}

public bool TryGetWatchValue(int nodeId, out double value)

{

return Procedure.TryGetWatchValue(nodeId, index, subindex, out value);

}

}

Script Features

Script features are extensions to the scripting functionality.

In order to use script features, the user must add

using emDrive_Configurator.Scripts.Features;Modbus TCP

This functionality is only available for emDrive Configurator 2.13.1.0 and later.

ModbusTCP currently supports connection with Modbus Servers (Client Mode) through TCP. In order to connect to the device, you need to provide the IP Address, Port and Modbus Server ID (Bus Address).

In the following Example, the IP is 127.0.0.1, the Port is 502 and the Modbus Server ID is 1:

ModbusTCP ModbusDevice1 = new ModbusTCP("127.0.0.1", 502, 1);Alternatively, the device endianness can also be specified in the connection constructor:

ModbusTCP ModbusLocalhost = new ModbusTCP("127.0.0.1", 502, 1, ModbusEndianness.LittleEndian);Default Endianness is set to Big Endian.

Currently Read and Write Holding registers operation is supported using generic functions:

short i16_var = 0;

// Read Holding Register at Address 100

if(ModbusLocalhost.ReadHoldingRegister<short>(100, out i16_var) == true)

{

// Read Successful

}

else

{

// Read Failed

}

// Write Holding Register at Address 100

ModbusLocalhost.WriteHoldingRegister(100, i16_var); Supported data types:

- short

- ushort

- int

- uint

- float

Useful Learning Resources

If you’re new to C# or need additional reading to get familiar with the language and its concepts, check out these established sources:

-

Microsoft C# Documentation:

Comprehensive reference and tutorials on the C# language.

https://docs.microsoft.com/en-us/dotnet/csharp/ -

C# Language Reference:

Detailed descriptions of language syntax, keywords, and code examples.

https://docs.microsoft.com/en-us/dotnet/csharp/language-reference/ -

.NET Tutorials:

Learn the fundamentals of C#, .NET Framework, and best practices.

https://docs.microsoft.com/en-us/dotnet/core/tutorials/

Additional Tips and Conclusion

Version Considerations

For scripts with long-running loops, ensure you are using version 2.9.0.0 or later, which supports using a CancellationToken.

Earlier versions (e.g., 2.5.4.0 and lower) require a different namespace (using eDrive_Configurator;).

Script Debugging

Utilize the Log output function (Procedure.Log) to print messages and debug your script during execution.

Integration with Watch

Use the WatchScriptObject class to monitor variable values during script execution. This can help you verify that the SDO read/write operations are working as expected.

By following this guide, even users with minimal technical expertise will be able to write, run, and troubleshoot simple C# scripts to interact with CAN Open devices via the emDrive Configurator. Experiment with the examples provided and consult the useful links if you need further insight into C# programming.

Happy scripting!

Parameters

Object's Attributes

Each CANopen Object in emDrive inverter has several attributes. Following attributes are related to changing, storing and loading values of objects.

| Attribute | Description |

| Access Type | Defines if the object is readable and/or writable |

| Default Value | Default value is value that the object is set to when setting parameters to factory/manufacturer defaults |

| Read Level | Access level that is required for reading value of object |

| Write Level | Access level that is required for writing value to object |

| Persistent | Defines if the value of object is saved in permanent storage (keeps value after reboot or power cycle) |

Object which have Persistent attribute set to "1" are stored in permanent memory and are therefore called "Parameters".

Objects attributes are visible in EDS or DCF files.

See Access Levels for more information about access to objects.

Parameters Sections

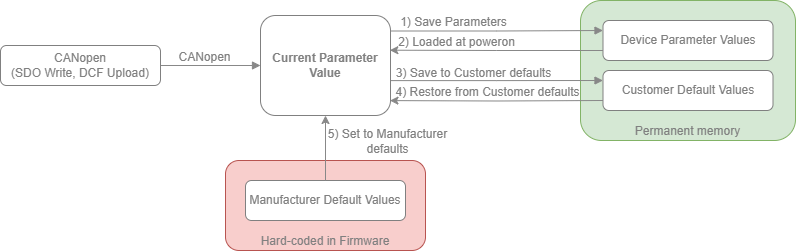

There are several different "sections" where parameters can be saved or restored from.

Current Parameter Values

Current value of parameter that is in use. This values are used by applications, firmware and can be access and changed via CANopen or custom CAN messages, depending on inverter.

Manufacturer Default Values

This values are hardcoded into firmware and are used to restore the device to factory default configuration. See section "Restore Manufacturer defaults - "Factory Reset" (5)"

Customer Default Values

Customer defaults is special section that can be used by Emsiso customer during their configuration or alternatively can be loaded at production. Customer has than the ability to reset configuration to their desired defaults i.e. "Customer defaults" without completely resetting parameters to factory defaults.

See sections "Saving to Customer defaults (3)" and "Restore Customer defaults (4)" on how to store values and restore values from this section.

Device Parameter Values

Parameter values stored into permanent memory that are loaded at every power up. See section "Saving Device parameters (1)" on how to save current configuration.

There is also addition section "Calibration parameter" which is used for calibration in production. Customer does not have access to it. Objects that are stored in that section will be loaded from that section at powerup.

Saving and Restoring Parameters

Saving Device parameters (1)

Saving parameters is done by SDO write to CANopen object with index 0x1010 - "Store_Parameters_Field". Writing value 0x73617665 (ASCII "save") or byte swapped value 0x65766173 to any of sub indexes 0x01-0x04. Return status of SDO write will indicate success of failure.

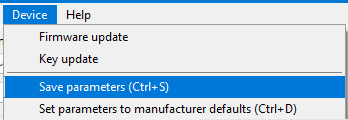

Saving can also be done within emDrive Configurator by selecting "Device" -> "Save parameters" or by using shortcut "CTRL + S".

Saving parameters in emDrive Configurator

Saving parameters in emDrive Configurator

Saving to Customer defaults (3)

Saving parameters to "Customer Defaults" section is done by SDO write to CANopen object with index 0x1010 - "Store_Parameters_Field". Writing value 0x73617665 (ASCII "save") or byte swapped value 0x65766173 to sub index 0x05 "Save_Customer_Defined_Parameters. Return status of SDO write will indicate success of failure.

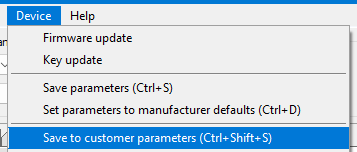

Saving can also be done within emDrive Configurator by selecting "Device" -> "Save to customer parameters" or by using shortcut "CTRL + SHIFT + S".

Saving parameters to Customer defaults in emDrive Configurator

Saving parameters to Customer defaults in emDrive Configurator

Saving to Customer defaults is only possible with Access Level 2 (Customer) or above.

Restore Manufacturer defaults - "Factory Reset" (5)

Restoring parameter values to manufacturer defaults is done by SDO write to CANopen object with index 0x1011 - "Restore_Default_Parameters". Writing value 0x6C6F6164 (ASCII "load") or byte swapped value 0x64616F6C to any of sub index 0x01-0x04. Return status of SDO write will indicate success of failure.

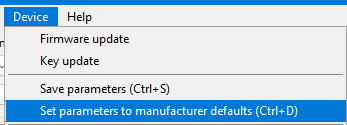

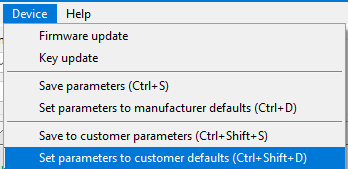

Restoring can also be done within emDrive Configurator by selecting "Device" -> "Set parameters to manufacturer defaults" or by using shortcut "CTRL + D".

Setting parameters to manufacturer defaults in emDrive Configurator

Restoring from manufacturer defaults is only possible with Access Level 2 (Customer) or above.

Restore Customer defaults (4)

Restoring parameter values to Customer defaults is done by SDO write to CANopen object with index 0x1011 - "Restore_Default_Parameters". Writing value 0x6C6F6164 (ASCII "load") or byte swapped value 0x64616F6C to sub index 0x05 "Restore_Cusstomer_Define_Default_Parameters. Return status of SDO write will indicate success of failure.

Restoring to Customer defaults can also be done within emDrive Configurator by selecting "Device" -> "Set parameters to customer defaults" or by using shortcut "CTRL + SHIFT + D".

Restoring parameters from Customer defaults in emDrive Configurator

Restoring parameters from Customer defaults in emDrive Configurator

After each operation device shall be reset to apply new values.

Access Level

Access Level functionality is different depending on the emDRIVE firmware version.

Up to V1.14.x

Access Level is emDrive functionality that is used to limit read and write permissions for objects depending on user granted access.

Access Level functionality is available from firmware V1.11.0 and newer.

Each Parameter has attribute (Object's Attributes) for Read and Write access level. To be able to read or write to object Inverter must be unlocked to required level.

Access Levels

| Level | Name | Description |

| 1 | End User | Object is available to End User even when inverter is locked with "Customer Key" |

| 2 | Customer | Object is available by default. Can be locked with "Customer Key" |

| 3 | Production | Object is available only in production to write production related and calibration objects (only Emsiso) |

| 4 | Development | Object is available only during development (only Emsiso) |

Devices shipped from manufacturer are unlocked to "Customer" level. Customer has the option to lock the device and prevent additional changing of object values from 3rd parties.

Access Level CANopen Objects

Objects at index 0x2010 are used for Access Level functionality

| Sub - index | Name | Description |

| 0x01 | Access_Level__Current | Shows current access level that inverter is set to, objects with equal or lower access level can be accessed. |

| 0x02 | Access_Level_Key_input | Write your key to unlock the device, depending on the key, specific level will be unlocked. |

| 0x03 | Access_Level_Customer_Key | Writing value to this object will lock the device to "End User" (after reset). The same key must be used to unlock the device to "Customer" level. Remove locking by writing value "0". |

Locking emDrive

Lock the emDrive inverter is intended to be used by Customer to prevent End User to make any changes of configuration. Objects with End User access level are mostly Read Only objects or only Read Access Level is set to End User.

To lock the emDrive follow the steps

- Chose the secret key that will be used to lock and unlock the inverter. Value can be from 1 - 4294967295 (32-bit unsigned integer).

- Write chosen key to object "Access_Level_Customer_Key"

- Save Device Parameters

- Reset the device

- After power up, device will have Current Access Level at 1 - End User. Check by reading object "Access_Level__Current"

Unlocking emDrive

If the emDrive is locked with Customer key and we want to change parameters that require Access Level 2, we have to unlock the emDrive after each power on. To verify that emDrive is locked, read object "Access_Level__Current" which should read "1".

To unlock the emDrive follow the steps

- Write correct Customer Key to object "Access_Level_Key_input".

- Read object "Access_Level__Current" which should change to "2" if the key was correct.

At this point Customer Level object can be read/written. But if the emDrive is reset, it will return to locked End User Access Level. To permanently unlock the emDrive and remove the key follow additional steps are needed.

- Write correct Customer Key to object "Access_Level_Key_input".

- Read object "Access_Level__Current" which should change to "2" if the key was correct.

- Write value "0" to "Access_Level_Customer_Key" to remove the key.

- Save Device Parameters

- Reset the device

- After power up, device will have Current Access Level at 2 - Customer. Check by reading object "Access_Level__Current"

V1.15.0+

Access Level is a feature of emDrive that controls read and write permissions for various objects based on the user’s granted access.

Access Level functionality is available from firmware V1.11.0 and newer.

Each parameter in emDrive has attributes (Object's Attributes) that define the required Read and Write Access Level. To interact with these parameters, the inverter must be unlocked to the corresponding access level. Higher access levels grant access to a greater number of objects.

Access Levels

| Level | Name | Description |

| 0 | End User | Available to the End User, even when the inverter is locked with the "Service Key". |

| 1 | Service | Available to Service personnel. Can be locked using the "Service Key". |

| 2 | Admin | Available by default. Can be locked using the "Admin Key". |

| 3 | Production | Accessible only in production for writing production-related and calibration objects (Emsiso). |

| 4 | Development | Accessible only during development (Emsiso). |

Devices shipped from the manufacturer are unlocked to the "Admin" level. The customer has the option to lock the device, preventing third parties from changing object values.

Access Level CANopen Objects

The following objects at index 0x2010 are used to control Access Level functionality:

| Sub - index | Name | Description |

| 0x01 | Access_Level__Current | Displays the current access level of the inverter. Objects with equal or lower levels can be accessed. |

| 0x02 | Access_Level__Key_input | Enter a key to unlock the device. The entered key will unlock a specific level. |

| 0x03 |

Access_Level__Admin_Key

|

Write a value to lock the device to "Admin" level after reset. Use the same key to unlock. Write "0" to remove locking. |

| 0x04 |

Access_Level__Service_Key

|

Write a value to lock the device to "Service" level after reset. Use the same key to unlock. Write "0" to remove locking. |

Locking emDrive

Locking the emDrive inverter is typically performed by the Admin or Service personnel to prevent the End User from making configuration changes. Objects accessible to the End User are usually read-only or have read-only permissions set.

To lock the emDrive follow the steps

- Choose a secret key (an integer between 1 and 4,294,967,295).

- Write the selected key to either the "Access_Level__Service_Key" or "Access_Level__Admin_Key" depending on the desired lock level.

- Save the device parameters.

- Reset the device

- After powering up, the device will be locked one level below the set key. Verify this by reading the "Access_Level__Current" object.

Unlocking emDrive

To modify parameters that require higher access levels (such as Admin or Service), the emDrive must be unlocked after every power cycle. To confirm that the emDrive is locked, check the "Access_Level__Current" object, which should display the correct locked level.

To unlock the emDrive:

- Write the correct key to the "Access_Level__Key_input" object.

- Read the "Access_Level__Current" object to verify the change to the corresponding access level.

Once unlocked, objects at the unlocked level can be accessed. However, if the emDrive is reset, it will revert to the locked state. To permanently unlock the emDrive, follow these additional steps:

- Write the correct key to the "Access_Level__Key_input" object.

- Verify that the access level has changed by reading "Access_Level__Current".

- Write the value "0" to "Access_Level__Admin_Key" or "Access_Level__Service_Key" to remove the respective key.

- Save the device parameters.

- Reset the device.

After the reset, the device will no longer require the key to access the previous locked level. You can verify this by checking the "Access_Level__Current" object.

Lua Manual

Disclaimer

The EMSISO d.o.o. scripting functionality, based on the Lua programming language, is provided to enable flexibility and customization for motor control applications. However, EMSISO d.o.o. assumes no responsibility or liability for any damages, malfunctions, injuries, or losses resulting from the use of scripts provided by EMSISO d.o.o. or scripts created, modified, or executed by users.

Users are fully responsible for testing and verifying all scripts in a controlled and safe environment before deployment. Any script used in conjunction with EMSISO d.o.o. products is done at the user’s own risk.

By using the scripting feature, you acknowledge and agree to release EMSISO d.o.o. from all claims, demands, or liability for any incidents that may arise from its use.

1. General

1.1 Purpose

- This manual helps you create and run Lua scripts on emDrive.

- It also informs you about any warnings and known issues.

1.2 Scope

- The manual covers Lua scripting features, including how to:

- Download scripts

- Control scripts

- Debug scripts

- Use functions provided by the emDrive library

- It also lists known issues and limitations of the scripting functionality.

1.3 Important Note

- This manual assumes you already know Lua and emDrive Configurator software.

- It is valid for Lua version 5.4. For more details on Lua, visit:

2. emDrive library

2.1 General

The emDrive library is used instead of the standard Lua libraries. This library includes some functions that are identical to those in the standard Lua library, some that have been modified, and others that are unique to emDrive.

Do not overwrite the emDrive library functions and variables.

The emDrive library is organized into different sets, each focused on a specific group of functionalities. This section will describe these sets and their functions and variables in detail.

Here is an example of how to use a library function. This example will show a legend that explains how to read the prototypes of library functions. Words in blue represent variable types, such as arguments or return values. These types follow standard Lua conventions, with the addition of the "integer" type, which represents whole numbers.

When your script calls a function from the emDrive library, the arguments you provide must match the prototype exactly, including the type and, for tables, their structure. If they do not, an error will occur.

number | nil ret1, boolean ret2 = Namespace.FunctionName({integer arg1Field1, string arg1Field2} arg1,

{integer, integer, integer [5:5-11], integer [13]} arg2, [, string arg3], arg4…)

This is an example of a function named Namespace.FunctionName. It takes in: 2 fixed arguments, 1 optional

argument and a variable number of arguments. It also returns 2 values where the first can also be nil.

|

|

Name |

Description |

|

Arguments |

arg1 |

Table with two named fields arg1Field1 of type integer and arg1Field2 of type string. |

|

arg2 |

Table with unnamed fields with all integer types at index 1, 2, 5 with size 1 to 7 and 13. |

|

|

arg3 |

Optional string argument. |

|

|

arg4 |

Variable number of arguments of any type. |

|

|

Returns |

ret1 |

First returned value which can be either a number type or nil. |

|

ret2 |

Second returned value which is of boolean type. |

Functions can be called with more arguments then expected in which case excess arguments are ignored.

The emDrive library can raise errors in addition to those raised by the Lua kernel, such as accessing nil values. These library errors usually occur when the type or value of an argument does not match what is expected.

For each function in the emDrive library, the possible errors (exceptions) and the conditions that cause them will be listed.

2.2 Functions

2.2.1 Base

This library provides base script functionality that is not specific to any part of the emDrive hardware (HW) or firmware (FW).

Error(string message [, integer level])

The Error function raises an error with a custom message and specifies the level of the error position. It is useful for throwing exceptions, such as for debugging purposes. This function is equivalent to the standard error() function in Lua and never returns.

|

|

Name |

Description |

|

Arguments |

message |

Error message shown. |

|

level |

Specify how to get the error position: · 0, error position is not added, · 1 (default), the error position is where the error() function was called, · 2 points the error to where the function that called error() was called, · and so on… |

2.2.2 I/O

This library works with two main objects: Lua__IO_Input and Lua__IO_Output. These objects facilitate communication between the script and the external world, such as displaying messages or providing debugging arguments to the script.

- Access: These objects can be accessed via the CANopen index

0x2040. - Purpose:

Lua__IO_Input: Used to input data into the script.Lua__IO_Output: Used to output data from the script.

By using these objects, the script can efficiently exchange information with external systems.

___________________________________________________________________________________________________________________________________________

number | string | nil value = IO.Read([option…])

You can read values from the input object using specified options.

Options:

- When the 'n' option is selected, if the value cannot be converted to a number,

nilis returned. - By passing an integer, you can read that many number of characters.

This function is equivalent to the standard io.read() function in Lua.

|

|

Name |

Description |

|

Arguments |

option |

How to interpret the input string: · ‘n’ as a number, · ‘l’ (default) as one line string without newline, · ‘L’ as one line string with newline if exists, · ‘a’ as string of all text, · 0, 1, 2, … as number of characters. |

|

Returns |

value |

Interpreted input. |

|

Exception |

|

option is not an integer nor a string. |

|

option is a string longer than 1 character. |

|

option is a string but not one of the valid values. |

___________________________________________________________________________________________________________________________________________

IO.Write(string text…)

You can write text to the output object using this function.

- Behavior:

- If the text is short enough, it is appended to the existing output string.

- If the text is too long, the existing output string is overwritten.

This function is equivalent to the standard io.write() function in Lua.

|

|

Name |

Description |

|

Arguments |

text |

Text to write to output object. |

|

Exception |

|

text is not a string. |

___________________________________________________________________________________________________________________________________________

IO.Print(object…)

This function converts an object to a string and then writes the result to the output object.

This function is equivalent to the standard print() function in Lua.

|

|

Name |

Description |

|

Arguments |

object |

Objects to convert to string and write to output object. |

2.2.3 Time

This library provides functions for time keeping and inserting delays in your scripts.

___________________________________________________________________________________________________________________________________________

integer time = Time.GetMs()

This function retrieves the current time in milliseconds since the device was powered on. The maximum value is limited to 2³² – 1.

|

|

Name |

Description |

|

Returns |

time |

Elapsed milliseconds since power on. |

___________________________________________________________________________________________________________________________________________

Time.WaitMs(integer time)

This function halts the script execution for a specified amount of time using this function.

|

|

Name |

Description |

|

Returns |

time |

Milliseconds to wait. |

|

Exception |

|

time is negative or 0. |

___________________________________________________________________________________________________________________________________________

integer newStartTime = Time.WaitMsUntil(integer startTime, integer waitTime)

This function halts script execution for specified time from the provided starting time. This function can be used to implement periodic execution independent of logic execution duration.

|

|

Name |

Description |

|

Arguments |

startTime |

Time (milliseconds) from which waiting time is measured. |

|

waitTime |

Milliseconds to wait. |

|

|

Returns |

newStartTime |

Time (milliseconds) at which script was halted. |

|

Exception |

|

startTime is negative or 0. |

|

waitTime is negative or 0. |

2.2.3 CAN

This library is used to establish communication and transfer data over CAN. It provides functionality to send and receive CAN messages.

Note: This library does not support CAN FD (Flexible Data-rate).

___________________________________________________________________________________________________________________________________________

This library supports two modes of operation for CAN communication. The mode is selected during the initialization of CAN.

|

Mode |

Description |

|

CAN_RX_TX |

CAN shall be used to send and receive messages (user is required to implement CAN.Received(message) function). |

|

CAN_TX_ONLY |

CAN shall be used only to send messages. |

___________________________________________________________________________________________________________________________________________

CAN.Initialize(mode, boolean useExtendedFrame [, integer rxID, integer rxIDMask])

To use CAN communication, initialize CAN with this function. It can be called multiple times with different arguments, but only the last configuration will be used.

- rxIDMask Argument: Required only when the operating mode is set to

CAN_RX_TX.

|

|

Name |

Description |

|

Arguments |

mode |

CAN mode of operation (see Table 12). |

|

useExtendedFrame |

Will extended frames be transferred? |

|

|

rxID |

Frame ID to receive. |

|

|

rxIDMask |

Receive filter ID mask. |

|

Exception |

|

mode is not one of the valid values. |

|

useExtendedFrame is not boolean. |

|

rxID is not an integer. |

|

mode is set to CAN_RX_TX and rxIDMask is not an integer. |

|

CAN initialization failed (should never happen). |

___________________________________________________________________________________________________________________________________________

CAN.Send(integer id, {integer [1:1-8]} data)

Use this function to send a CAN frame with a specified ID and data.

|

|

Name |

Description |

|

Arguments |

id |

Sent frame ID. |

|

data |

1 to 8 bytes of data. |

|

Exception |

|

id is not an integer. |

|

data is not a table. |

|

Length of data is more than 8. |

|

Value of data is not an integer. |

|

Value of data is more than 0xFF. |

|

CAN send failed (should never happen). |

___________________________________________________________________________________________________________________________________________

CAN.Received({integer ID, integer Length, integer Data[1:1-8]} message)

This function is called whenever a CAN message is received.

- User Implementation Required: You must implement this function if CAN is initialized in

CAN_RX_TXoperating mode.

|

|

Name |

Description |

|

Arguments |

message |

Received message. |

2.2.4 CANopen

This library is used to interact with the CANopen protocol stack.

- CANopen Object Representation: Internally, a CANopen object is represented as a table with two values:

indexandsubindex.

___________________________________________________________________________________________________________________________________________

The CANopen stack includes a network management state machine that defines the communication behavior of a CANopen device. While there are multiple possible states, only a few are regularly used and available to the user.

|

NMT state |

Description |

|

CO_UNKNOWN |

NMT in unknown state (unreachable). This state cannot be set by user. |

|

CO_OPERATIONAL |

Device can use all supported communication objects. This state can be set by user. |

|

CO_STOPPED |

Device operation is stopped. This state cannot be set by user. |

|

CO_PREOPERATIONAL |

First state after initialization indicating that device is ready to work. Limited message transfer support. This state can be set by user. |

|

CO_RESET_NODE |

Application reset. Application objects set to their power-on or default values. This state cannot be set by user. |

|

CO_RESET_COMM |

Communication reset. Communication objects are set to their power-on or default values. This state cannot be set by user. |

___________________________________________________________________________________________________________________________________________

state = CANopen.GetNMTState()

Use this function to retrieve the currently set Network Management (NMT) state of the CANopen device.

|

|

Name |

Description |

|

Arguments |

state |

Currently set NMT state (see Table 18). |

___________________________________________________________________________________________________________________________________________

CANopen.SetNMTState(state)

Use this function to request the CANopen stack to change the Network Management (NMT) state of the device.

|

|

Name |

Description |

|

Arguments |

state |

Next NMT state (see Table 18). |

|

Exception |

|

state is not one of the valid values. |

___________________________________________________________________________________________________________________________________________

number value = CANopen.GetObjectValue({integer, integer} object)

Use this function to retrieve the value of a specified object.

|

|

Name |

Description |

|

Arguments |

object |

CANopen object. |

|

Returns |

value |

Object value. |

|

Exception |

|

object is not a table. |

|

Length of object is not 2. |

|

Value at first index of object is not an integer. |

|

Value at second index of object is not an integer. |

|

Invalid object index and/or subindex. |

___________________________________________________________________________________________________________________________________________

CANopen.SetObjectValue({integer, integer} object, number value)

Use this function to set the value of a specified object.

|

|

Name |

Description |

|

Arguments |

object |

CANopen object. |

|

value |

Object value. |

|

Exception |

|

object is not a table. |

|

Length of object is not 2. |

|

Value at first index of object is not an integer. |

|

Value at second index of object is not an integer. |

|

Invalid object index and/or subindex. |

|

Value is not a number |

2.2.5 Motor

This library is used to operate the motor. You can set operating parameters and retrieve the motor's current state and status.

___________________________________________________________________________________________________________________________________________

The motor can be controlled in three distinct modes. Depending on the chosen mode, the related reference will be used by the motor control algorithm.

|

Motor control mode |

Description |

|

TORQUE_MODE |

Motor is torque controlled. Set requested torque with Motor.SetReferenceTorque(). |

|

VELOCITY_MODE |

Motor is velocity controlled. Set requested velocity with Motor.SetReferenceVelocity(). |

|

POSITION_MODE |

Motor is position controlled. Set requested torque with Motor.SetReferencePosition(). |

___________________________________________________________________________________________________________________________________________

Motor control operates with a state machine that can be in one of multiple states. This state machine is responsible for top-level motor control functions such as initialization, execution, calibration, and error handling.

- State Execution: Some states are executed before the script runs and will not be visible to the user.

|

Motor control state |

Description |

|

MOTOR_UNDEFINED |

Motor control in undefined state (internal error). |

|

MOTOR_INITIALIZATION |

Motor control is initializing. |

|

MOTOR_SELF_TEST |

Motor control is performing start-up self-tests. |

|

MOTOR_OFF |

Motor control is initialized and disabled. Controlling the motor is not possible. Reference values have no effect. |

|

MOTOR_ON |

Motor control is initialized and enabled. Motor is controlled according to mode and reference value such that the operating conditions are always within defined limits. |

|

MOTOR_ERROR |

Motor control detected an error and was disabled. This state can be entered in multiple ways: limits overreached, failed calibration and other. |

|

MOTOR_CALIBRATION |

Motor control is being calibrated. In this state characteristics of the motor and angle sensor are being measured. |

___________________________________________________________________________________________________________________________________________

Motor.Enable()

Enable motor control to have the motor operate according to the set mode and the corresponding reference value.

___________________________________________________________________________________________________________________________________________

Motor.Disable()

Disable motor control to stop the motor.

___________________________________________________________________________________________________________________________________________

Motor.Recover()

Use this function to attempt recovery from a motor control error.

Note: This function is only applicable when the motor control is in an error state.

___________________________________________________________________________________________________________________________________________

Motor.SetControlMode(mode)

Use this function to set the motor control mode.

|

|

Name |

Description |

|

Arguments |

mode |

Motor control mode (see Table 26). |

|

Exception |

|

mode is not one of the valid values. |

___________________________________________________________________________________________________________________________________________

state = Motor.GetState()

Retrieve the current state of the motor control.

|

|

Name |

Description |

|

Returns |

state |

Motor control state (see Table 27). |

___________________________________________________________________________________________________________________________________________

integer warnings = Motor.GetWarnings()

Retrieve the currently active motor control warnings.

|

|

Name |

Description |

|

Returns |

warnings |

Active warnings. Refer to emDrive manual or related CANopen object for value meaning. |

___________________________________________________________________________________________________________________________________________

integer protectionsLow = Motor.GetProtectionsLow()

Retrieve the currently active motor control protections (first 32 bits).

|

|

Name |

Description |

|

Returns |

protectionsLow |

Active protections (first 32bits). Refer to emDrive manual or related CANopen object for value meaning. |

___________________________________________________________________________________________________________________________________________

integer protectionsHigh = Motor.GetProtectionsHigh()

Retrieve the currently active motor control protections (last 32 bits).

|

|

Name |

Description |

|

Returns |

protectionsHigh |

Active protections (second 32 bits - currently empty meant for future FW releases). Refer to emDrive manual or related CANopen object for value meaning. |

___________________________________________________________________________________________________________________________________________

number velocity = Motor.GetReferenceVelocity()

Retrieve the currently set reference velocity.

|

|

Name |

Description |

|

Returns |

velocity |

Velocity [RPM]. |

___________________________________________________________________________________________________________________________________________

Motor.SetReferenceVelocity(number velocity)

Set the reference velocity.

|

|

Name |

Description |

|

Arguments |

velocity |

Velocity [RPM]. |

|

Exception |

|

velocity is not a number. |

___________________________________________________________________________________________________________________________________________

number torque = Motor.GetReferenceTorque()

Retrieve the currently set reference torque.

|

|

Name |

Description |

|

Returns |

torque |

Torque [Nm]. |

___________________________________________________________________________________________________________________________________________

Motor.SetReferenceTorque(number torque)

Set the reference torque.

|

|

Name |

Description |

|

Arguments |

torque |

Torque [Nm]. |

|

Exception |

|

torque is not a number. |

___________________________________________________________________________________________________________________________________________

number position = Motor.GetReferencePosition()

Retrieve the currently set reference position.

|

|

Name |

Description |

|

Returns |

position |

Position [°]. |

___________________________________________________________________________________________________________________________________________

Motor.SetReferencePosition(number position)

Set the reference position.

|

|

Name |

Description |

|

Arguments |

position |

Position [°C]. |

|

Exception |

|

position is not a number. |

___________________________________________________________________________________________________________________________________________

number velocity = Motor.GetVelocity()

Retrieve the current motor velocity.

|

|

Name |

Description |

|

Returns |

velocity |

Velocity [RPM]. |

___________________________________________________________________________________________________________________________________________

number torque = Motor.GetTorque()

Retrieve the current motor torque.

|

|

Name |

Description |

|

Returns |

torque |

Torque [Nm]. |

___________________________________________________________________________________________________________________________________________

number position = Motor.GetPosition()

Retrieve the current motor position.

|

|

Name |

Description |

|

Returns |

position |

Position [°C]. |

___________________________________________________________________________________________________________________________________________

Motor.TriggerProtection(number ErrorCode, string ErrorMessage)

Raise inverter protection from Lua

|

|

Name |

Description |

|

Arguments |

ErrorCode |

Create custom value for error code |

|

|

ErrorMessage |

Custom error description |

|

Exception |

|

ErrorCode is not a number |

2.2.6 Digital

This library is used to manipulate digital I/Os (ports). It enables writing to and reading from digital ports.

___________________________________________________________________________________________________________________________________________

Every emDrive contains a set of digital ports that can be freely used by the user application. Some of these ports are writable, while others are read-only. Note that some ports might not be available on all emDrives. To see which ports are available, refer to the manual or the EDS of your emDrive

|

Digital port |

Description |

|

LOW_SIDE_1 |

Low-side switch 1. |

|

LOW_SIDE_2 |

Low-side switch 2. |

|

LOW_SIDE_3 |

Low-side switch 3. |

|

LOW_SIDE_4 |

Low-side switch 4. |

|

HIGH_SIDE_1 |

High-side switch 1. |

|

DIGITAL_IN_1 |

Digital input 1. This port is read-only. |

|

DIGITAL_IN_2 |

Digital input 2. This port is read-only. |

|

DIGITAL_IN_3 |

Digital input 3. This port is read-only. |

|

DIGITAL_IN_4 |

Digital input 4. This port is read-only. |

|

DIGITAL_IN_5 |

Digital input 5. This port is read-only. |

|

DIGITAL_IN_6 |

Digital input 6. This port is read-only. |

|

DIGITAL_IN_7 |

Digital input 7. This port is read-only. |

___________________________________________________________________________________________________________________________________________

number state = Digital.Get(port)

Retrieve the digital state of the port.

|

|

Name |

Description |

|

Arguments |

port |

Digital port (see Table 44). |

|

Returns |

state |

Value of 0 – 1 representing signal’s duty cycle. |

|

Exception |

|

port is not one of the valid values. |

___________________________________________________________________________________________________________________________________________

Digital.Set(port, number state)

Set the digital state of the port.

|

|

Name |

Description |

|

Arguments |

port |

Digital port (see Table 44). |

|

state |

Value of 0 – 1 representing signal’s duty cycle. |

|

Exception |

|

port is not one of the valid values. |

|

state is not a number between 0 and 1. |

___________________________________________________________________________________________________________________________________________

2.2.7 Analog

This library is used to retrieve values from analog inputs (ports).

___________________________________________________________________________________________________________________________________________

Every emDrive contains a set of analog ports that can be freely used by the user application. All of these ports are read-only. Note that some ports might not be available on all emDrives. To see which ports are available, refer to the manual or the EDS of your emDrive.

|

Analog port |

Description |

|

ANALOG_IN_1 |

Analog input 1. |

|

ANALOG_IN_2 |

Analog input 2. |

|

ANALOG_IN_3 |

Analog input 3. |

|

ANALOG_IN_4 |

Analog input 4. |

|

LOW_SIDE_1_VOLTAGE |

Low-side switch 1 voltage measurement. |

|

LOW_SIDE_1_CURRENT |

Low-side switch 1 current measurement. |

|

LOW_SIDE_2_VOLTAGE |

Low-side switch 2 voltage measurement. |

|

LOW_SIDE_3_VOLTAGE |

Low-side switch 3 voltage measurement. |

|

LOW_SIDE_4_VOLTAGE |

Low-side switch 4 voltage measurement. |

|

HIGH_SIDE_1_VOLTAGE |

High-side switch 1 voltage measurement. |

|

DIGITAL_IN_1 |

Digital input 1. |

|

DIGITAL_IN_2 |

Digital input 2. |

|

DIGITAL_IN_3 |

Digital input 3. |

|

DIGITAL_IN_4 |

Digital input 4. |

|

DIGITAL_IN_5 |

Digital input 5. |

|

DIGITAL_IN_6 |

Digital input 6. |

|

DIGITAL_IN_7 |

Digital input 7. |

___________________________________________________________________________________________________________________________________________

number value = Analog.Get(port)

Retrieve the analog value on the port.

|

|

Name |

Description |

|

Arguments |

port |

Analog port (see Table 49). |

|

Returns |

value |

Analog value. |

|

Exception |

|

port is not one of the valid values. |

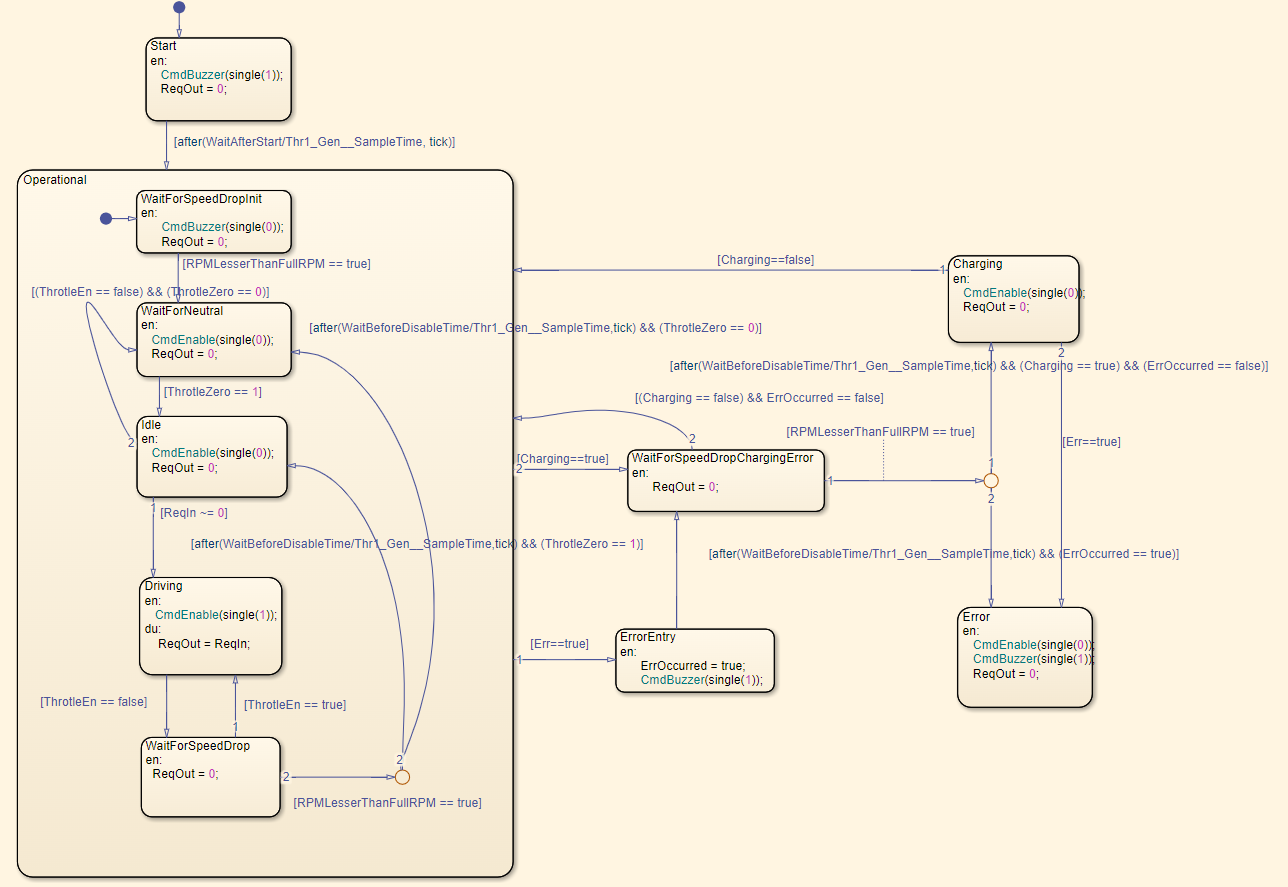

3. Scripting

3.1 Setting Up Lua Scripting with Visual Studio Code

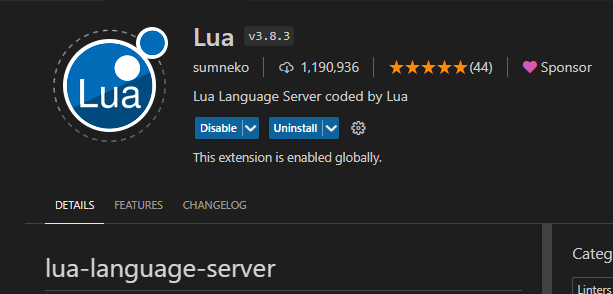

To make Lua scripting easier, follow these steps to set up Visual Studio Code with the Lua extension:

-

Install Visual Studio Code

- If you don't have it yet, download and install Visual Studio Code.

-

Add the Lua Extension

-

Create a Folder for Libraries

- Make a new folder on your computer to store the emdrive library. For example, you can name it

D:\LuaLibraries. - Inside the folder extract the emdrive.7z which you get directly from us.

D:\LuaLibraries\emdrive

- Make a new folder on your computer to store the emdrive library. For example, you can name it

-

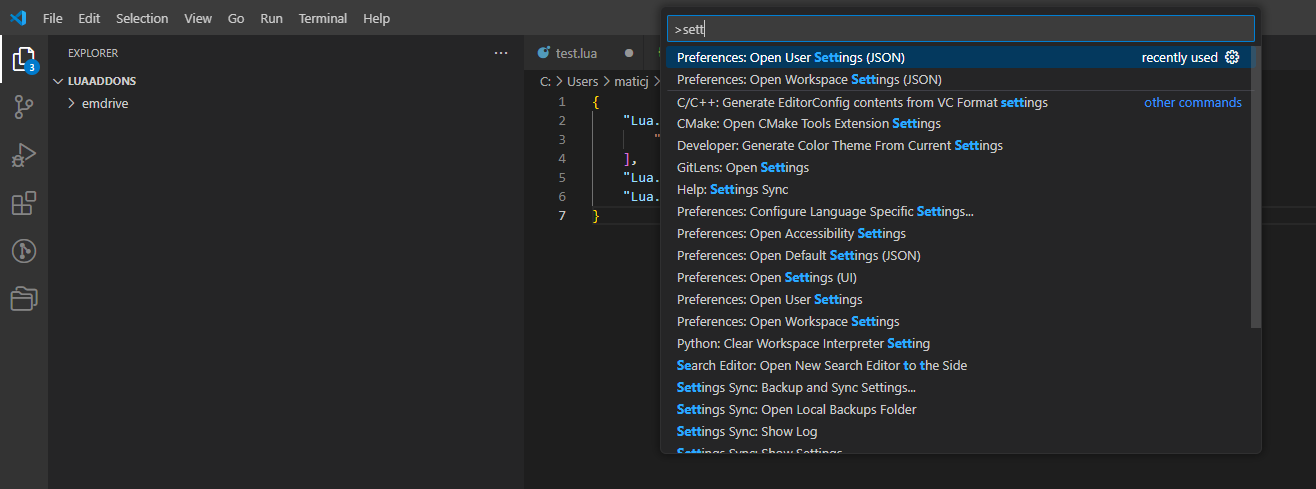

Configure Developer Mode and Add Library Path

-

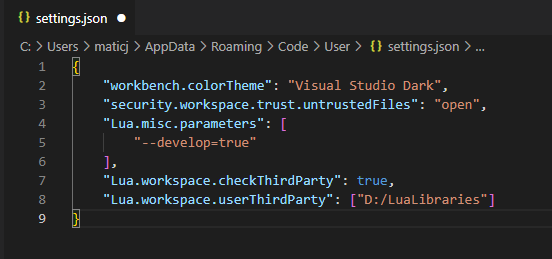

Edit User Settings (JSON)

- In the opened

settings.jsonfile, add the following code.

"Lua.misc.parameters": [ "--develop=true" ], "Lua.workspace.checkThirdParty": true, "Lua.workspace.userThirdParty": ["path_to_our_library"] - Make sure to keep any existing code intact. Add a comma at the end of the last line of the existing code, then paste the new code below it. Update the path to match your folder (

D:/LuaLibraries). Use forward slashes instead of backslashes.

- In the opened

-

Save and Close

- Save the changes to

settings.json. - Close Visual Studio Code.

- Save the changes to

Example of "settings.json":

3.2 Getting Started with Lua Scripting

3.2.1 Create "firstscript.lua"

-

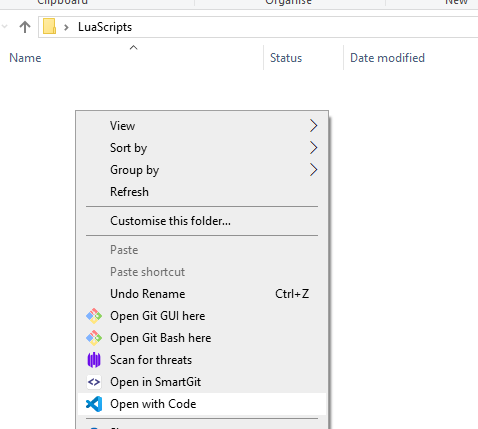

Create a New Folder

- Make a new folder for your project.

-

Open the Folder with Visual Studio Code

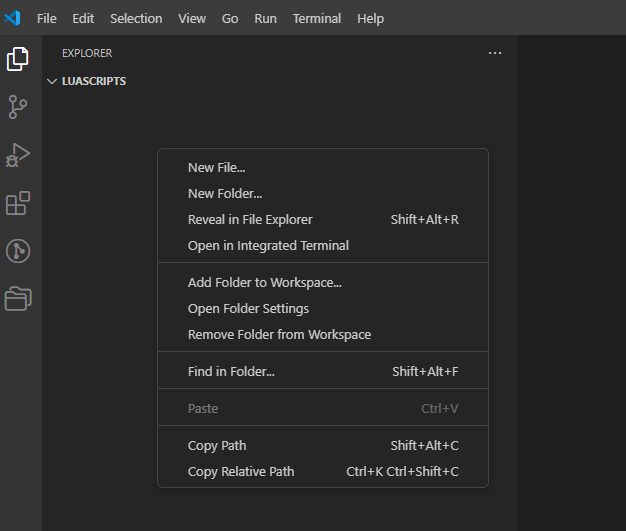

-

Create a New Lua Script

Note: Only the content of the script is transferred, not the file name.

Limitation: You can store only one script at a time on the emDrive.

3.2.2 Structure

Initialization Routine

- Function Requirement: Your script must include a function named

Initialize(). - Execution: This function is the first to run when the script is executed and runs only once.

- Purpose: Use this function to initialize hardware and firmware, such as:

- Setting up CAN

- Enabling the motor

- Setting outputs

- Setting global variables

Loop Routine

- Function Requirement: Your script must include a function named

Loop(). - Periodic Execution: This function runs periodically based on the

LoopPeriodMsvariable, which represents the period in milliseconds.- Setting the Period:

LoopPeriodMscan be set globally or within theInitialize()function.

- Setting the Period:

- Purpose: Use the

Loop()function for tasks that need regular updates, such as:- Setting motor velocity

- Parsing CAN frames

- Reading inputs and setting output ports

Minimum Loop Period: The minimum allowed loop period is 10 milliseconds.

Execution Time: Ensure the Loop() function completes within the set period to maintain deterministic execution. If the loop takes longer, it can cause unpredictable behavior.

Priority Consideration: The firmware on the emDrive has higher priority than the script, which means script execution may be interrupted by higher priority tasks.

Use the resource monitor (see the Resource Monitor section) to measure loop duration and determine the minimum possible loop period.

The resource monitor can also show the maximum loop duration when interrupted by higher priority tasks.

Data Transfer: Transferring large data over CAN/CANopen will completely block script execution.

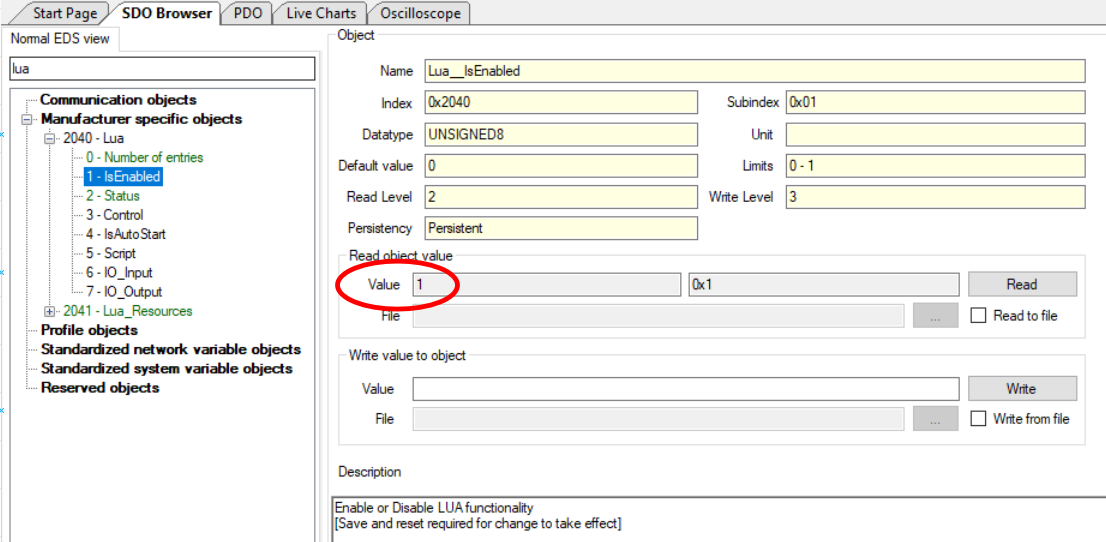

3.3 Executing script

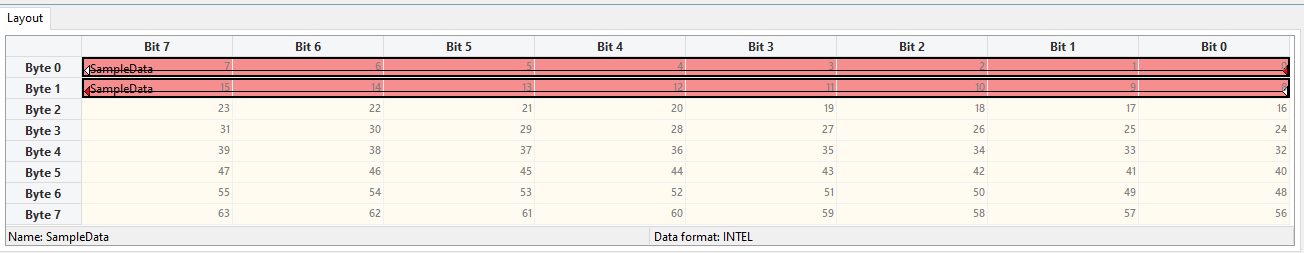

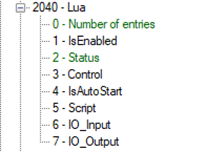

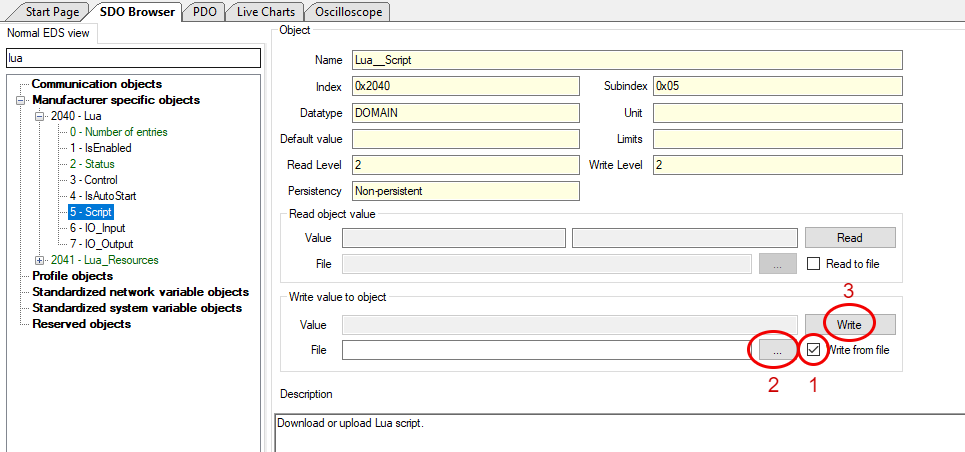

After you've created your script, it is time to download it to emDrive and execute it. For these purposes, a few CANopen objects are provided, as seen in Figure 3. They are grouped together and are accessible at index 0x2040.

Table 52 provides a short description of objects related to script execution. More detailed meanings and use cases will be presented in the following sections.

|

Name |

Description |

|

IsEnabled |

Defines if Lua feature is enabled on particular emDrive: 0: Lua feature disabled 1: Lua feature enabled |

|

Status |

Lua status: 0: File is non-existent or corrupted, 1: Compilation failed (see Output), 2: Execution failed (see Output), 3: Downloaded file is valid, 4: Script execution is paused, 5: Script is executing, 6: Script timed out and was stopped. |

|

Control |

Lua script control: 0: Do nothing, 1: Pause, 2: Run, 3: Restart. |

|

IsAutoStart |

Should script be started automatically after device powers on? |

|

Script |

Download or upload Lua script. |

|

IO_Input |

Script input object. This object can be used to pass values/arguments to the script during runtime. |

|

IO_Output |

Script output object. This object is used to display error messages and can be used by script to print arbitrary text messages. |

|

Error_Code |

Used to show the value of error raised inside lua script. If this object is not 0, the inverter will go into error state. |

|

Error_Message |

Used to show the appropriate error description for the specific error code. |

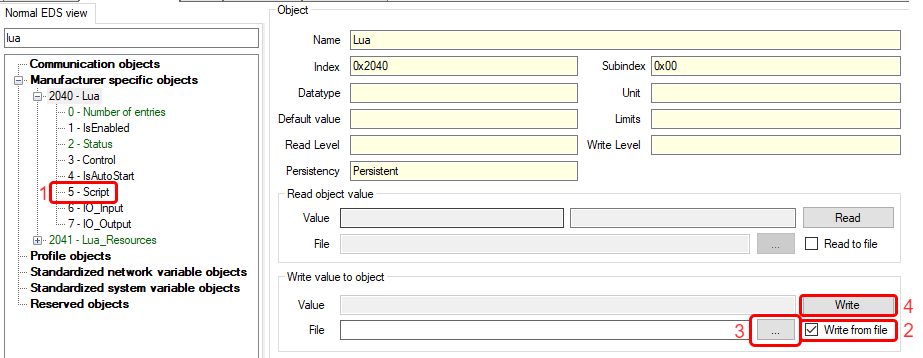

3.3.1 Download/Upload

- To download the script to emDrive

- click on Script object (0x2040, 0x5),

- check “Write from file”,

- click the “…” button which brings up an open file dialog where you select your script,

- click “Write” button which will download the script to emDrive,

- after successful download you should see a green progress bar with “Successful” label.

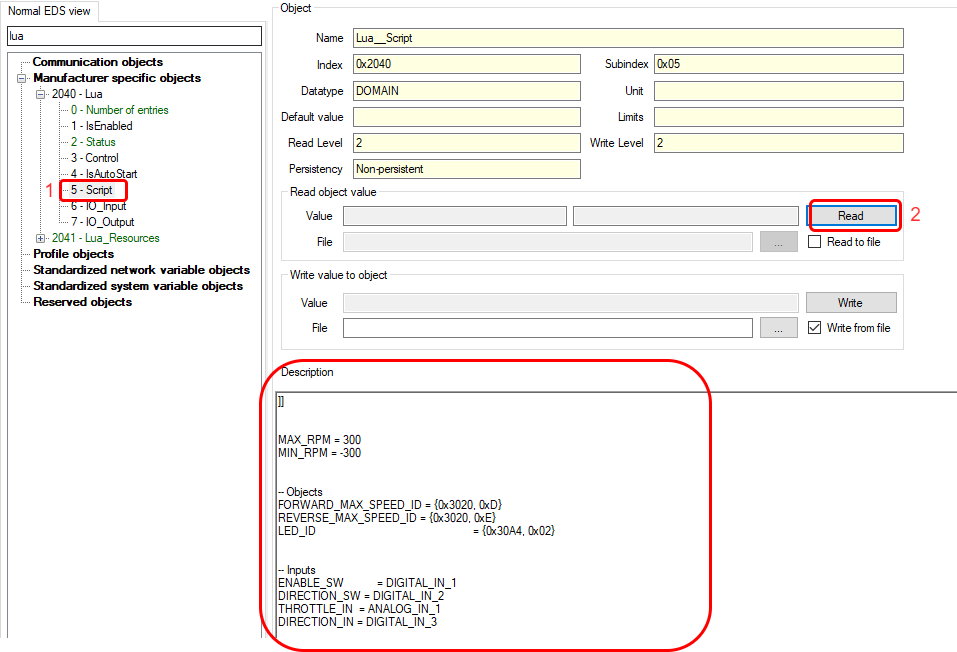

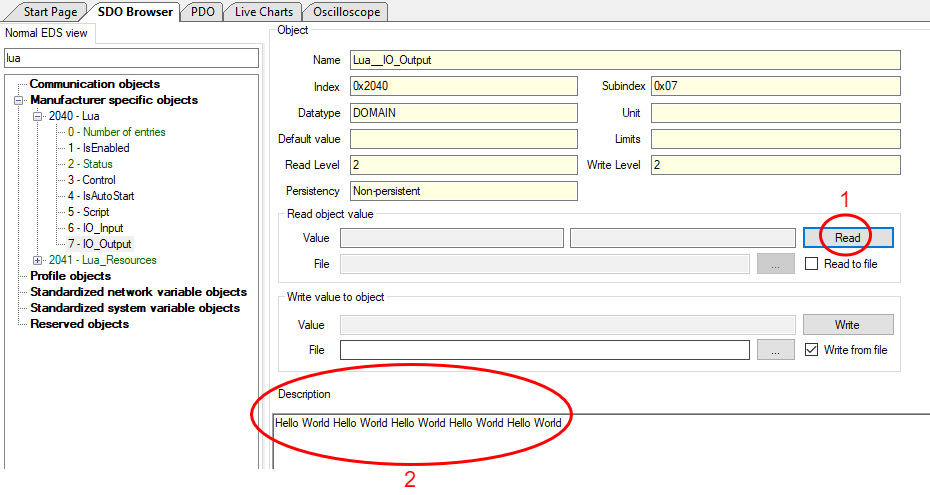

- To upload the script – this reads back the script currently stored on emDrive:

- click on Script object (0x2040, 0x5),

- click the “Read” button which will upload the script from emDrive and display it in the “Description” text box.

3.3.2 Control

Once the script has been successfully downloaded and verified, three control options become available through the Control object (0x2040, 0x3).

If a script is already executing when a new script is downloaded, the executing script is terminated as the download is initiated. After the new script is successfully downloaded and verified, it is automatically executed.

NOTE: The script is executed only after motor control has been initialized, which may delay script execution after the device powers on (usually by approximately 100 ms, although this value may vary).

3.3.3 Errors

When an error with the script is detected, the Status object (0x2040, 0x2) is set to a value signaling the type of error. There are four distinct types of errors that are detectable at different stages of script execution:

-

File is non-existent or corrupted (Status = 0): This is set when the script is not stored on the emDrive, or the stored script is corrupted. This error is triggered when script verification fails, either when the device powers on or whenever a new script is downloaded.

-

Compilation failed (Status = 1): This is set when the script could not be compiled, which could be caused by syntax errors or running out of memory. This error is triggered every time script compilation fails, such as when the script is restarted, executed for the first time, or downloaded while another script is already executing, causing the new script to be automatically compiled after downloading.

-

Execution failed (Status = 2): This is set when an error occurs during runtime—such as in initialization, loop, or other required routines—caused by several reasons like accessing nil objects, passing invalid values, missing functions, running out of memory, and others. This error is also raised if the

Error()function is called from within the script. -

Script timed out and was stopped (Status = 6): This is set when the initialization, loop, or other required routines take longer to execute than expected.

The initialization routine must execute within 100 ms, while the loop and other routines are required to execute within 2 × LoopPeriodMs.

Further details of what went wrong with the script can be retrieved from the output object.

All the above-mentioned errors are permanent. When an error is raised, emDrive protection is activated, and emDrive enters an error state from which it cannot recover (refer to the emDrive manual for more details about protections and error states). At this point, the script should be corrected for errors, downloaded to the emDrive, and then the device should be reset to clear the error.

3.3.4 Debugging

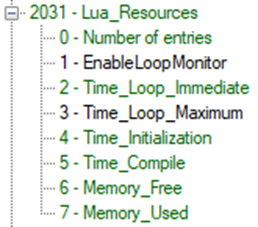

There is no proper debugging mechanism in place; however, utilizing Lua I/O objects and general-purpose CANopen objects, some form of limited debugging is possible. Using the input object, the user can control the flow of the program. The user can also write debug information to the output object. Additionally, all objects at index 0x3020, can be used freely for debugging purposes.

3.3.5 Resource monitor

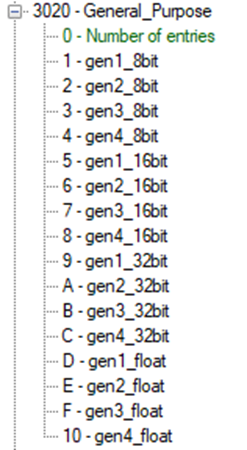

The resource monitor is used to measure characteristics of the script during compile-time, initialization, and runtime (loop). All available objects relevant to resource monitoring are shown under object 0x2031 and described in Table 53.

|

Name |

Description |

|

EnableLoopMonitor |

Enable loop resource monitoring which includes execution time and RAM usage. |

|

Time_Loop_Immediate |

Immediate measured loop duration [us]. |

|

Time_Loop_Maximum |

Maximum measured loop duration [us].

This value might sometimes appear unreasonably large that is when task running Lua script gets interrupted by higher priority tasks.

Write 0 to clear value and prepare it for new measurement. |

|

Time_Initialization |

Time [ms] required to execute initialization routine. |

|

Time_Compile |

Time [ms] required to load the script - that is time to script initialization. |

|

Memory_Free |

Immediately available RAM [byte]. |

|

Memory_Used |

Immediately used RAM [byte]. |

Initialization and compile-time measurements are performed every time a new script is downloaded and executed or when an existing script is restarted. Memory and loop time monitoring must be explicitly enabled by setting EnableLoopMonitor to 1. This is because these measurements are calculated every loop, thereby shortening the processing time allocated to the script.

3.4 Using the emdrive Library

3.4.1 Option 1: Automatic Setup

-

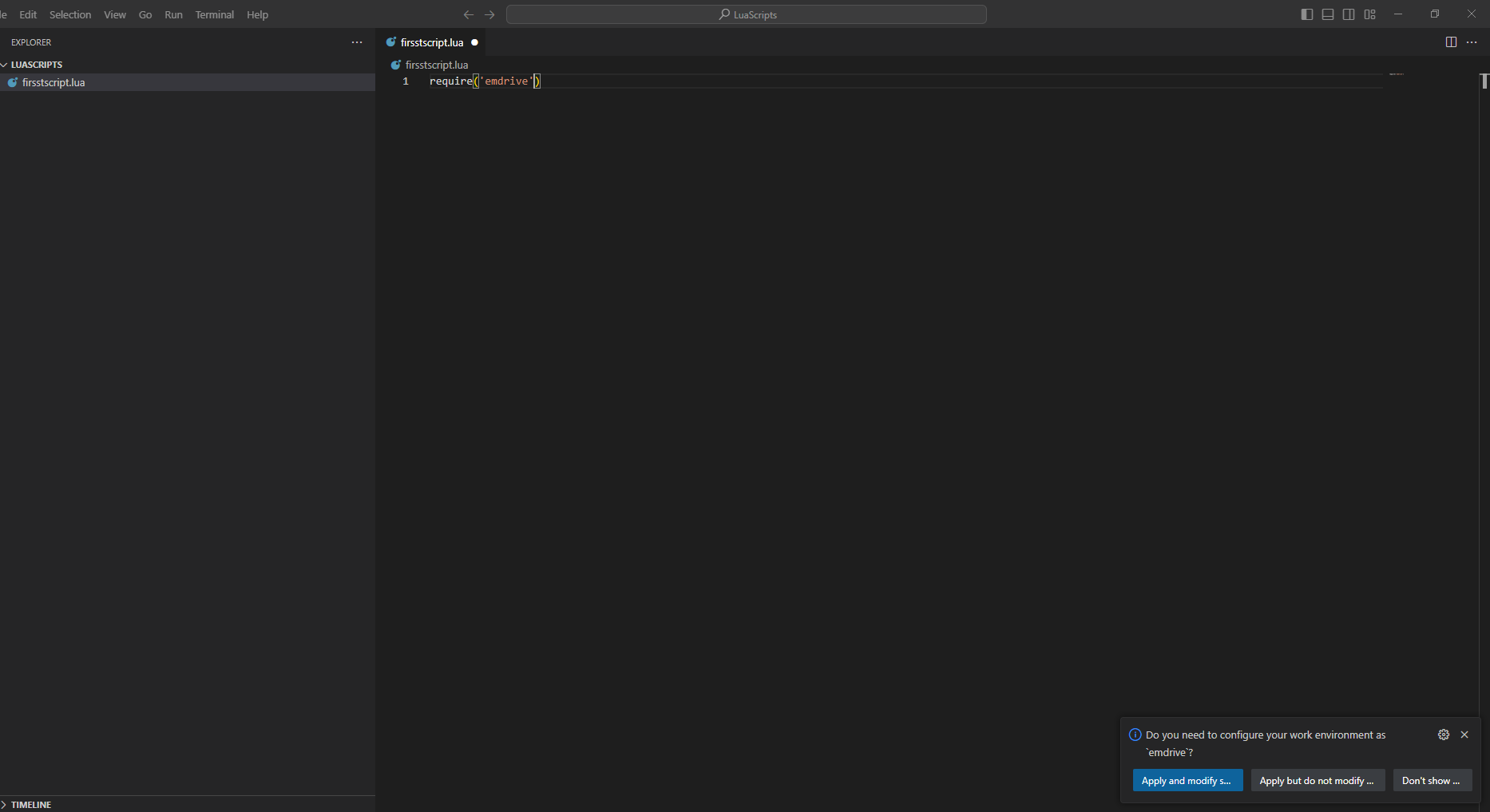

Add Code to Script

- In

firstscript.lua, add the following line:

require('emdrive')

- In

-

Apply Path Modification

-

Check .vscode Folder

- A new folder named

.vscodewill be created. - Inside, there will be a

settings.jsonfile containing the path to the library.

- A new folder named

3.4.2 Option 2: Manual Setup

-

Create .vscode Folder

- Manually create a

.vscodefolder in your workspace.

- Manually create a

-

Create settings.json File

- Inside the

.vscodefolder, create asettings.jsonfile.

- Inside the

-

Add Library Path to settings.json

- Add the following code to

settings.json:{ "lua.workspace.library": [ "D:/LuaLibraries" ] }

- Add the following code to

4. Examples

4.1 Example 1: "Hello World"

Description:

Print "Hello World" every 100ms to IO_Output.

To make the script work, you need to have two functions: Initialize and Loop.

-

Copy the Code

Copy the following code to an

example.luafile:function Initialize() LoopPeriodMs = 100 end function Loop() IO.Write("Hello World ") end -

Load the Script on the Inverter

- Go to

0x2040 0x05 - Script. - Select "Write from file" and click "...".

- A pop-up window will appear. Locate the saved script and click "Open".

- Click "Write".

- Go to

-

Check if the Script is Valid

- Go to

0x2040 0x02 - Status. - The value "3" indicates the downloaded file is valid.

- Go to

-

Run the Script

- Set

0x2040 0x03 - Controlto2. - If the script is running, the status value should be "5".

- Set

-

View the Output

- Go to

0x2040 0x07 - IO_output. - Click "Read" to see the "Hello World" string in the Description window.

- Go to

4.2 Example 2: Data types & variables

4.2.1 Example 2.1: Data types

Lua is a lightweight, high-level programming language known for its simplicity and flexibility. It has several basic data types, each serving a different purpose. Here are the main data types in Lua along with examples for each:

- Nil

Represents the absence of a value. - Boolean

Represents a boolean value, either true or false. - Number

Represents both integer and floating-point numbers. - String

Represents a sequence of characters. - Table

Represents associative arrays, which can be used as arrays, dictionaries, or other data structures. - Function

Represents a callable function.

function Initialize()

LoopPeriodMs = 100

end

function Loop()

-- 1. Nil

local myVariable = nil

IO.Print(myVariable) -- Output: nil

-- 2. Boolean

local isTrue = true

local isFalse = false

IO.Print(isTrue) -- Output: true

IO.Print(isFalse) -- Output: false

-- 3. Number

local integerNumber = 42

local floatingNumber = 3.14

IO.Print(integerNumber) -- Output: 42

IO.Print(floatingNumber) -- Output: 3.14

-- 4. String

local myString = "Hello, Lua!"

IO.Print(myString) -- Output: Hello, Lua!

-- 5. Table

local myTable = { key1 = "value1", key2 = "value2" }

IO.Print(myTable.key1) -- Output: value1

IO.Print(myTable.key2) -- Output: value2

local arrayTable = { "apple", "banana", "cherry" }

IO.Print(arrayTable[1]) -- Output: apple

-- 6. Function

local function myFunction(a, b)

return a + b

end

IO.Print(myFunction(2, 3)) -- Output: 5

-- 6. Anonymous function

local anonFunction = function(x, y)

return x * y

end

IO.Print(anonFunction(4, 5)) -- Output: 20

end4.2.2 Example 2.2: Variables

- Global variables

Global variables are accessible from anywhere in the program unless shadowed by a local variable of the same name. By default, any variable declared without thelocalkeyword is global.

myGlobalVariable = 10 -- Global variable function printGlobal() print(myGlobalVariable) end printGlobal() -- Output: 10 - Local Variables

Local variables are only accessible within the block or function where they are declared. They help avoid polluting the global namespace and can be used to manage scope more effectively.

local myLocalVariable = 20 -- Local variable function printLocal() local myLocalVariable = 30 -- Local to this function print(myLocalVariable) end printLocal() -- Output: 30 print(myLocalVariable) -- Output: 20 - Table fields

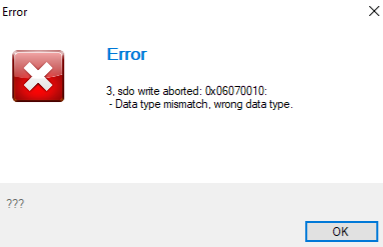

Variables can also be fields of tables, allowing for the creation of more complex data structures like arrays, dictionaries, and objects.